Direct Prep 4 is a powerful cleaning agent that can be used on new or recycled mesh, or even hard surfaces in the screen department

Rotary Textile

Printing Product Portfolio

Home > Screen Printing > Textile Printing > Rotary Textile Printing

Rotary Printing Emulsion: SAATItex + Textil

Rotary Printing Emulsion: SAATItex + Textil

SAATItex Rotary CTS

- Low viscosity one part photopolymer emulsion, compatible with industrial discharges

- Remarkable wet adhesion during the developing process

- Very high mechanical & chemical resistance

- Developed for Direct Light & Direct Laser imaging & exposure

- Excellent resolution for fine lines & half-tone printing

- Outstanding adhesion to nickel screens

SAATItex Rotary DTR

- Lorem ipsum odor amet, consectetuer adipiscing elit.

- Parturient sollicitudin inceptos donec integer dapibus, odio pharetra senectus?

- Vivamus aliquet platea, augue torquent metus justo varius.

SAATItex Rotary DTR TDS - EMEA+China - COMING SOON

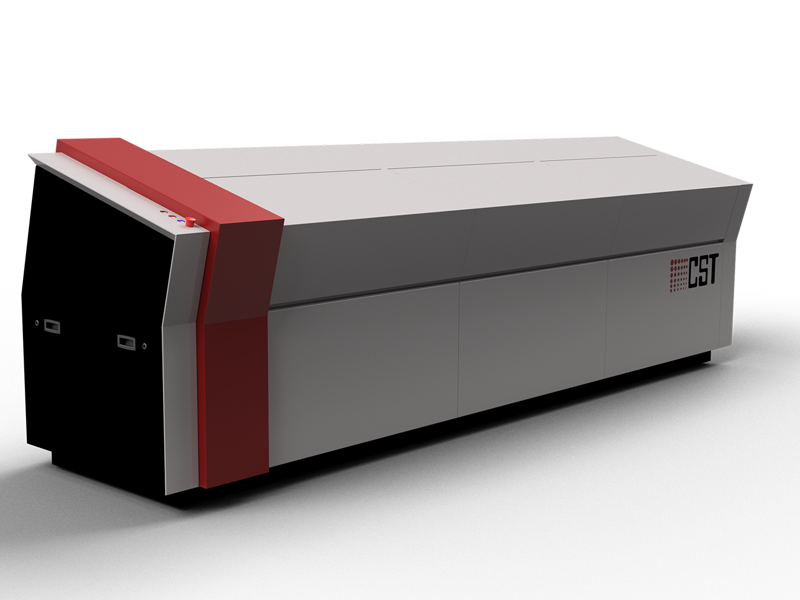

CST Imaging & Exposure

CST Imaging & Exposure

CST DLE Rotary

- Easy handling

- Compact design

- Fast and high-quality engraving

CST DLE Rotary+

- 2400 DPI Resolution

- HD Chip (1920x1080)

- Laser Light Source

- Easy handling

- Compact design

- Fast and high-quality engraving

Pro-Lite Exposure

Pro-Lite Exposure

SAATI Pro-Lite 450 Exposure Lamp

The sustainable targeted wavelength LED exposure lamp with super low energy requirements

Blockouts & Screen Sealers

Blockouts & Screen Sealers

Finish S1

Red, medium viscosity solids-resistant blockout

Finish S2

Blue, medium viscosity solvent-resistant blockout

Finish S3

Blue, high viscosity solvent-resistant blockout

Finish W1

Purple, high solids content water-resistant blockout

Finish W3

Purple, high solids content water-resistant blockout

Finish WU2 A&B

Red, solvent-resistant screen filler that also accelerates polyurethane adhesive curing times

Finish SU1 A&B

Red, solvent-resistant screen filler

Quality Control Devices

Quality Control Devices

Yellow LED Safelight Bulbs

Yellow LED Safelights permit you to brightly illuminate the areas where you store, transport and prepare screens for exposure. With a light “airlock” it’s possible to work comfortably without compromising stencil quality. SAATI Yellow LED Safelights are the preferred solution

Safe Light Goggles

Safe light goggles are an essential tool for every screen printing business. Safe light goggles ignore the wavelengths that are safe for unexposed stencil material and only allow the wearer to see in the wavelengths that do affect them. Instantly verify the presence or absence of unsafe light wavelengths in the areas where you store, transport and prepare to expose unexposed screens, so you can take decisive action with Safe lighting as needed.

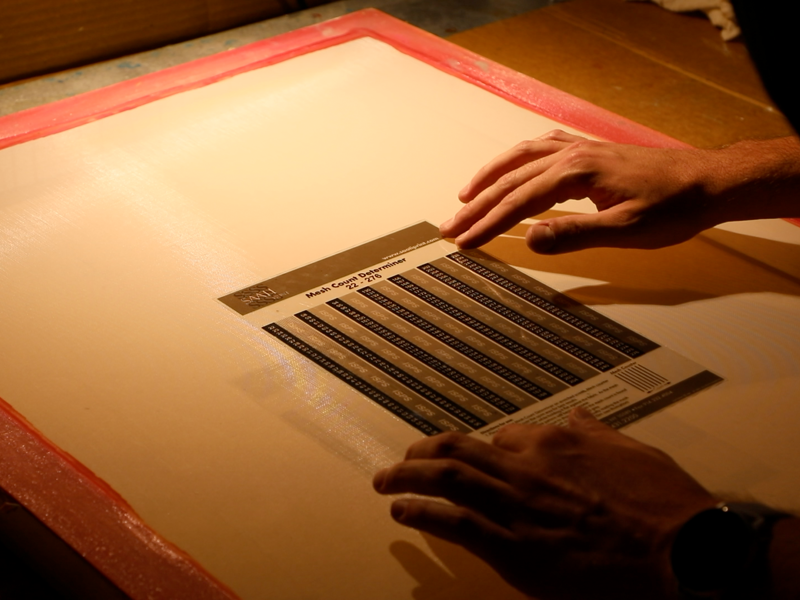

Mesh Counter

Accurately count the number of threads per inch within +/-2 in mesh counts ranging from 22-528 TPI.

This is accomplished by placing one of the 2 included films (22-276 TPI and 274-528 TPI) onto your fabric and rotating the film until the moire pattern appears next to the mesh count.

Digital Tension Meter

Confirm the tension of your mesh during stretching, and at all subsequent stages to avoid printing with under-tensioned screens

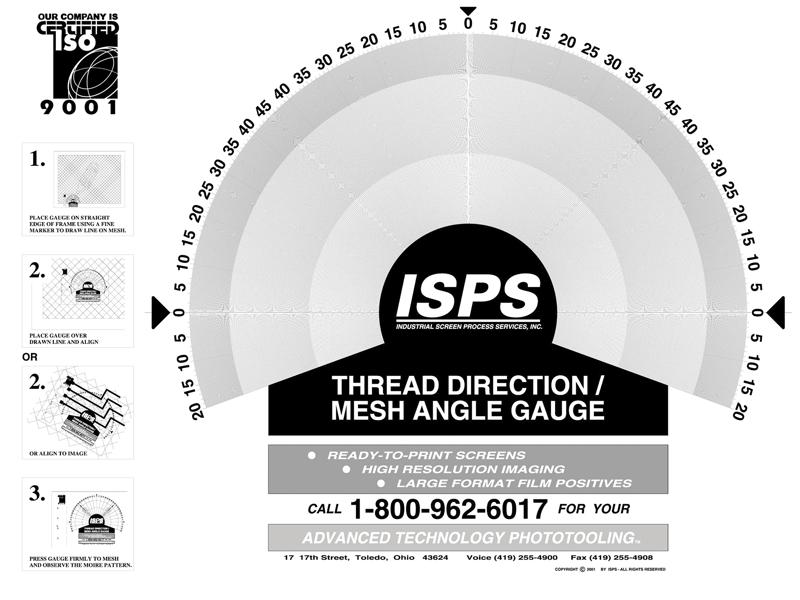

Angle Determiner

Use gauge by laying it directly on the screen or film. A moiré pattern appears on the tool at the angle it sees.

Newman Tension Meter

The only analog tension meter in the world with all stainless steel hardened gears, and shock-proof industrial-grade internal gear movement

Positector 6000 Thickness Gauge

Use this digital gauge to measure the EOM of your screens prior to exposure so that your exposure program and eventual ink deposits will be correct

Positector DFT Thickness Gauge

Use this digital gauge to measure the EOM of your screens prior to exposure so that your exposure program and eventual ink deposits will be correct

Roughness (Rz) Meter

Use this digital gauge to measure the peaks and valleys of your stencil surface to understand if the surface is too rough or too smooth to create precise ink deposits

TQM Aquacheck

When diazo/dual-cure stencils are moist and are exposed in that condition, they suffer from loss of resolution, and any moist screen can also stick to vacuum glass. With a Moisture Meter, it is simple and quick to confirm that a coated screen is fully dried before subjecting it to an exposure program.

Spectrophotometer

This small, light weight portable spectrophotometer is designed for easy operation and high precision for a variety of functions. It measures the wavelength and output interval of light sources in your screenmaking area - both the exposure equipment and ambient lighting

21 Step Guide

SAATI’s 21 Step Guide is a day one priority for every screen printer across every application. This small tool is applied to the stencil material prior to exposure, and when developed tells you whether the stencil has over or under exposure, or is dialed in for the best print quality. Count the number of progressively darker steps of the calculator that have adhered to the mesh, and make one simple calculation to prepare a second test and confirm perfect stencil curing.

Take it one step further and apply the calculator to every screen you produce - you will know with certainty that every screen going to press is dialed in for high resolution and durability.

Exposure Calculator

This handy guide is fixed to emulsion prior to exposure and upon developing reveals resolution and definition for 4 progressively shorter exposure times – 70%, 50%, 33% and 25% of the actual test. Compare the results between steps to make an informed decision about what result matches your exact needs.

Rex H-1000 Durometer Gauge

A compact and simple to read tool that confirms squeegee hardness for blades without a stated value, it also helps you identify squeegee that have softened, so you always go to press with the right blade for accurate printed results.

ViTiny 300 Plus Microscope

This powerful handheld microscope allows you to check your halftones on substrates, to check whether details have narrowed or closed prior to printing, and to check the quality of the edge definition with up to 200x magnification

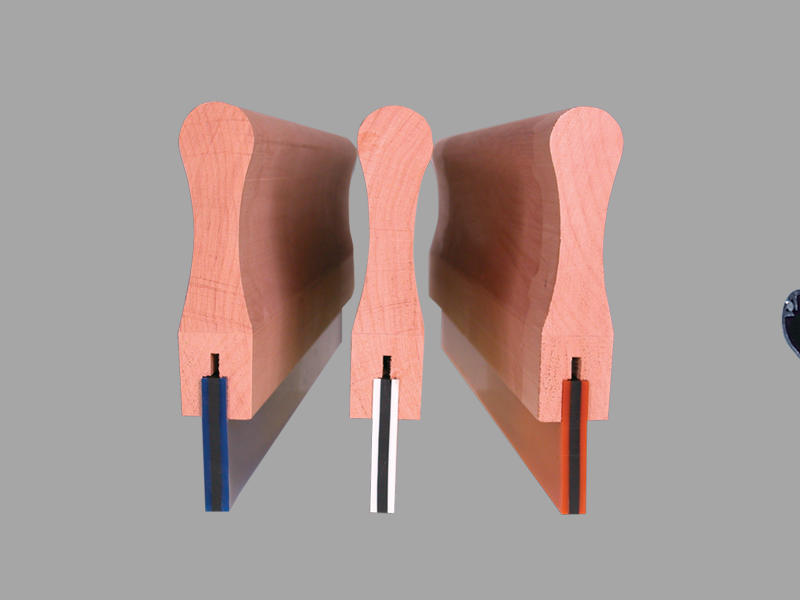

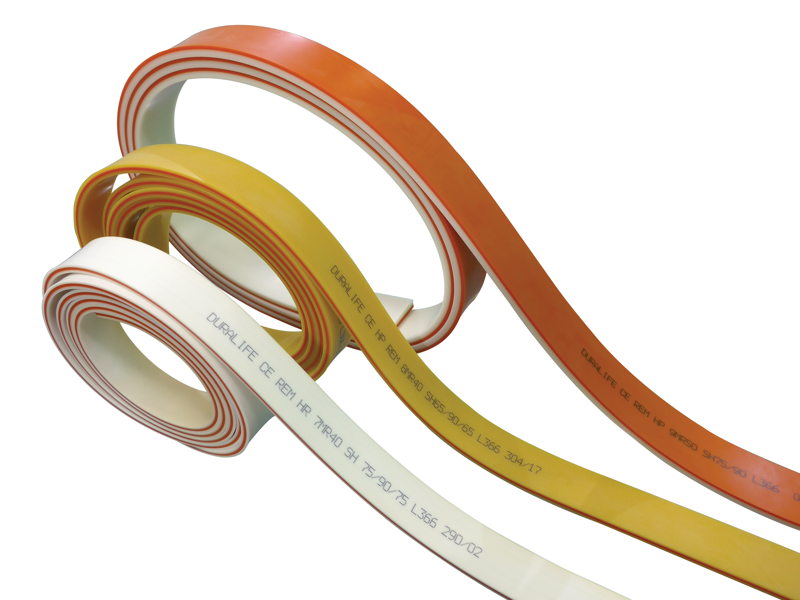

Duralife Squeegee

Duralife Squeegee

Duralife CE Cut Edge Squeegee

Resistant to both chemicals and abrasion making them suitable for all applications.

Assembled Duralife CE Cut Edge Squeegee

SAATI offers squeegee already installed into handles in either wood or extruded aluminium. Save set up time and a decision making step with our optimized handles rigorously tested for dependability and comfort on long print runs.

Duralife ME Molded Edge Squeegee

The only squeegee cast in individual cavity molds for the highest and resist both softening and nicking for longer than other products.

Duralife HP / MSR Molded Edge Squeegee

Premium squeegee for the most aggressive UV & solvent-based inks and demanding high speed automated printing like electronics and glass.

Duralife T-Vee Squeegee for Automated Textile Printing

The Duralife T-Vee Squeegee is a V-shaped molded edge squeegee specifically intended for textile applications with machine printing, in a hassle-free vertical orientation.

Press Wash

Press Wash

Remove PW1 Universal Product

- Fastest evaporating press wash

- Works on most inks

- VOC free

Remove PW7 Universal Product

- Recommended for use with Solvent based, UV-Cured inks and 2-part inks

- Flash point 43ºC/110ºF

- Fast drying product that is highly effective on difficult to clean inks

- Can be used to remove pallet adhesives on press

Remove PW13 Universal Product

- Press wash recommended for use with Solvent-Based, UV-Cured and Textile inks

- Flash point 62ºC/143ºF

- Contains no chlorinated solvents or toxic organic substances

- Compatible with automatic cleaning machines

- When used in automatic machines can be recycled through the vacuum distillation process

- Slower drying product that is highly effective on difficult to clean inks

Remove PW30 Universal Product

- Recommended for use with Solvent-Based, UV-Cured and Textile inks

- Flash point 43ºC/109ºF

- Compatible with automatic cleaning machines

- When used in automatic machines can be recycled through the vacuum distillation process

- Mild Scent

Remove PW36 Universal Product

- Recommended for use with Solvent-Based, UV-Cured and Textile inks

- Flash point 43ºC/109ºF

- Compatible with automatic cleaning machines

- When used in automatic machines can be recycled through the vacuum distillation process

- Mild Scent

Remove PW40 Universal Product

- Recommended for use with Solvent-Based, UV-Cured and Textile inks

- Flash point 43ºC/109ºF

- Compatible with automatic cleaning machines

- When used in automatic machines can be recycled through the vacuum distillation process

Remove PW3 Textile Product

- Textile Press Wash recommended for use with Plastisol and UV-Cured inks

- High flash point of 66ºC

- Low VOC <500g/L

Remove PW4 Textile Product

- Recommended for use with Plastisol and UV-Cured inks

- Flash point 49ºC/120ºF

- Medium drying speed

Remove PW9 Textile Product

- Textile Press Wash recommended for use with Plastisol inks

- Flash point 61ºC/142ºF

- Economical

- Will not lock up plastisol resistant only emulsions

- When wiped with cotton rag, masking tape will stick immediately

Remove PW10 Textile Product

- Recommended for use with Plastisol inks

- Flash point 61ºC/142ºF

- Apple scent

- Economical

- Will not lock up plastisol resistant only emulsions

- When wiped with cotton rag, masking tape will stick immediately

Remove PW8 SCAQMD Compliant Product

- Recommended for use on all inks

- Flash point >94ºC/>200ºF

- Low VOC at 90g/L and complies with SCAQMD regulations

- Non-flammable

Ink Removers

Ink Removers

Remove IR10 Universal Product

- Flash Point 150ºF (66ºC)

- Safe to use on emulsions that are plastisol resistant only

- Will not attack SAATI Chemicals CA Series Adhesives

Remove IR26 Universal Product

- Flash Point >200ºF (93ºC)

- Low foam & low odor and can be used for manual or automatic cleaning

- Can be mixed with Remove ER6 and used as one-step ink & stencil remover solution

- Emulsifies for easy water rinsing and avoids formation of ghost images

- High efficiency formula reduces product consumption

- Universal performance reduces the need for multiple ink removers

- Can be re-applied after stencil removal to remove ghost images

Remove IR27 Universal Product

- Flash point >200ºF (93ºC)

- Lower foam & low odor and can be used for manual or automatic cleaning

- Can be mixed with Remove ER products and used as one-step ink & stencil remover solution

- Emulsifies for easy water rinsing and avoids formation of ghost images

- Eliminates mesh stains when used to remove plastisol inks

- High efficiency formula reduces product consumption

- Universal performance reduces the need for multiple ink removers

- Can be re-applied after stencil removal to reduce ghost images

Remove IR29 Universal Product

- Flash point >200ºF (93ºC)

- No foam & low odor and can be used for manual or automatic cleaning

- Can be mixed with Remove ER products and used as one-step ink & stencil remover solution

- Emulsifies for easy water rinsing and avoids formation of ghost images

- High efficiency formula reduces product consumption

- Universal performance reduces the need for multiple ink removers

- Can be re-applied after stencil removal to reduce ghost images

Remove IR33 Universal Product

- Flash point >200ºF (93ºC)

- No foam & low odor and can be used for manual or automatic cleaning

- Can be mixed with Remove ER products and used as one-step ink & stencil remover solution

- Emulsifies for easy water rinsing and avoids formation of ghost images

- High efficiency formula reduces product consumption

- Universal performance reduces the need for multiple ink removers

- Can be re-applied after stencil removal to reduce ghost images

Remove IR3 Textile Product

- Ideal for garment and textile applications

- Works on all plastisol inks

- Use in spray or recirculating tanks

Remove IR4 Textile Product

- Ideal for garment and textile applications

- Works on all plastisol inks

- Use in spray or recirculating tanks

Remove IR5 Textile Product

- Flash Point 135ºF (57ºC)

- High efficiency formula

- Works well manually or in automatic systems

- Significantly reduces ink staining

- Solubilize ink then rinse with water

- Low mesh staining

Remove IR14 Textile Product

- Flash point 160ºF (71ºC)

- Pleasant scent

- Slightly viscous to improve cling to screen during application

- High efficiency formula reduces product consumption

- Clean screens with water and easy rinsing formula

- Low VOC’s at 289g/L

Remove IR19 Textile Product

- Flash Point >200ºF (93ºC)

- Economical

- Slightly viscous to improve cling to screen during application

- Low VOC at 139g/L

- High efficiency formula reduces product consumption

- Clean screens with water and easy rinsing formula

Remove IR8 SCAQMD Textile Product

- Textile ink remover

- Flash Point >200ºF (93ºC)

- Slightly viscous to improve cling to screen during application

- Low VOC at 93g/L and complies with SCAQMD regulations

- Non-flammable

Remove IR17 Universal SCAQMD Product

- Universal ink remover

- Flash Point >200ºF (93ºC)

- Non-flammable

- Zero VOC at 0g/L and complies with SCAQMD regulations

- High efficiency formula reduces product consumption

- Universal performance reduces the need for multiple ink removers

- Highly effective and can be reapplied to remove ghost image after stencil removal

Remove IR23 Universal GOTS Certified Product

- Universal ink remover recommended for use with Solvent-Based, UV-Cured and Textile inks

- Flash Point >80ºC / 176ºF

- Contains no chlorinated solvents or toxic organic substances

- GOTS-certified

- When used in automatic machines can be recycled through the vacuum distillation process

- Mild Odor

Remove IR24 Universal Biodegradable Product

- Universal ink remover recommended for use with Solvent-Based, UV-Cured and Textile inks

- Flash Point >80ºC / 176ºF

- Contains no chlorinated solvents or toxic organic substances

- GOTS-certified

- When used in automatic machines can be recycled through the vacuum distillation process

- Mild Odor

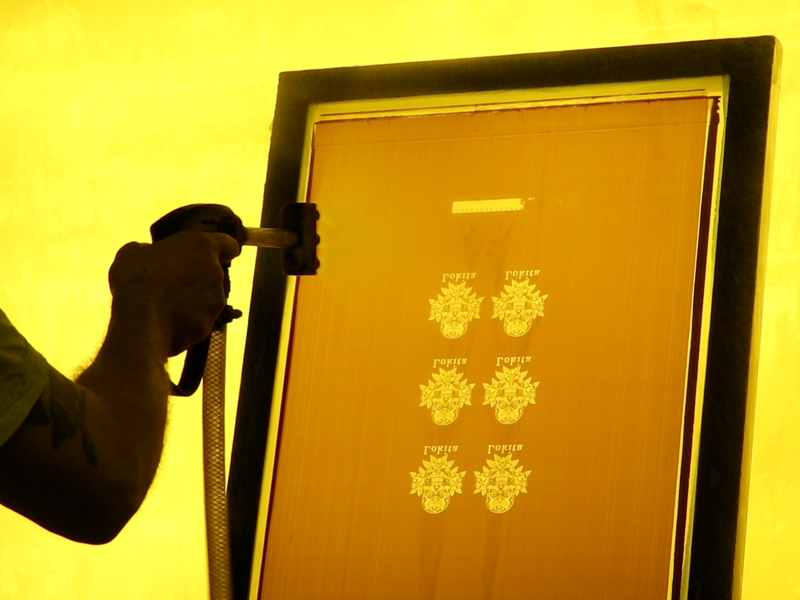

Emulsion Removers

Emulsion Removers

Remove ER4 Ready-Use Gel

- Ready to use gel emulsion remover

- Easy to apply by brush

- Smooth gel that spreads easily and stays put, for maximum effectiveness

- Contains built in degreaser that cuts through any ink/solvent residue to ensure fast and efficient stencil removal

Remove ER1 Powder for Dilution

- Concentrated emulsion remover powder that dissolves in water to produce stencil stripper solution

- Economical

- Highly concentrated product

- Recommended to be dissolved at 1% by weight in water for full strength working solution for spray application

Remove ER2 Concentrated Liquid

- Liquid concentrated emulsion remover that includes powerful built-in degreaser

- Dilute 1:35 by volume, or 1:25 by weight to provide full strength working solution for spray application

- Very easy to dissolve and will not crystallize

- Degreaser cuts through any greasy film left after ink removal and this ensures fast and efficient stencil removal

Remove ER5 Concentrated Liquid

- Liquid concentrated emulsion remover that mixes 1 part product with 4 parts water

- Economical product for spray application

- Very easy to dissolve and will not crystallize

Remove ER10 Concentrated Liquid

- Economical

- Most concentrated liquid reclaimer

- Dilutes 1:80 by volume or 1:50 by weight to make full strength working solution for spray application

- Can be diluted up to 300:1 by volume or 200:1 by weight, depending on requirements for use in automated screen recycling systems

- Will not crystallize or block spray nozzles

Remove ER13 Concentrated Liquid

- Super concentrated liquid emulsion remover

- Economical

- Highly concentrated liquid reclaimer

- Dilutes 1:40 by volume or 1:25 by weight to make a full strength working solution for spray application

- Can be diluted up to 150:1 by volume or 100:1 by weight, depending on requirements for use in automated screen recycling systems

- Will not block spray nozzles

Remove ER25 Concentrated Liquid

- Super concentrated liquid emulsion remover

- Economical

- Highly concentrated liquid reclaimer

- Dilutes 1:40 by volume or 1:25 by weight to make a full strength working solution for spray application

- Can be diluted up to 150:1 by volume or 100:1 by weight, depending on requirements for use in automated screen recycling systems

- Will not block spray nozzles

Remove ER26 Concentrated Liquid

- Low cost liquid concentrated emulsion remover with built-in degreaser

- Dilute 1:25 with water to provide working solution

- Easy to dissolve and will not crystallize

- Removes all types of emulsion or capillary film stencils

Haze Removers

Haze Removers

Remove HR2 Liquid Product

- Ready to use liquid haze remover

- Removes the toughest stains

- Works in minutes

- Viscous cling to prevent run off and minimize waste

- Powerful formula is able to remove older stains

Remove HR5 Liquid Product

- Powerful ready to use liquid haze remover

- Removes the toughest stains

- Works in minutes

- Viscous cling to prevent run off and minimize waste

- Works without the irritation and ‘bite’ normally associated with high caustic products

Remove HR12 Liquid Product

- Ready to use liquid haze remover

- Remove the toughest stains

- Works in minutes

- Low odor during use with pressure washer

- Viscous cling to prevent run off and minimize waste

- Powerful formula is able to remove older stains

- Designed to work on both wet or dry screens

Remove HR1 Gel Product

- Ready to use gel designed to remove diazo stains

- Combine with Remove IR for improved ink removal

- Can be left to dry on mesh and then reactivated with solvent for simplified batch cleaning of screens

- Low caustic formula will not pop screens

Remove HR3 Gel Product

- Ready to use haze remover paste

- Strong yet gentle on mesh

- Smooth gel spreads easily

- Stable formula does not separate or darken

- Will not separate in can when used with wet brush

Remove HR9 Gel Product

- Powerful fast acting gel that works in minutes

- One part, ready to use formula removes the toughest stains

- Low odor during use with pressure washer

- Fast and easy application with stainless steel scoop coater

- Non-drip and works only where applied

Remove HR4 Gel Product

- Ready to use non-caustic gel

- Designed to remove emulsion and ink residue

- Apply by scoop coater for easy batch cleaning of screens

- Can be left on screen for extended periods and will not weaken mesh

Remove HR6 Stain Remover

- Pink, semi-viscous liquid/gel

- Non-caustic

- Mild cherry scent

- Effectively removes ink stain from most recent job

- Mild abrasive formula helps to speed stain removal

Hand Cleaners

Hand Cleaners

Remove HC8 Hand Cleaner

- Pink, viscous, water-based lotion

- Pleasant cherry scent

- Moisturizes skin while cleaning inks, oils and more

- Contains medium-grit abrasive to accelerate the removal of difficult soils

Green Apple Hand Cleaner

- Viscous light green water-based lotion

- Pleasant green apple scent

- Moisturizes skin while cleaning inks, oils and more

- Contains fine-grit abrasive to accelerate the removal of difficult soils

Screen Printing Accessories

Screen Printing Accessories

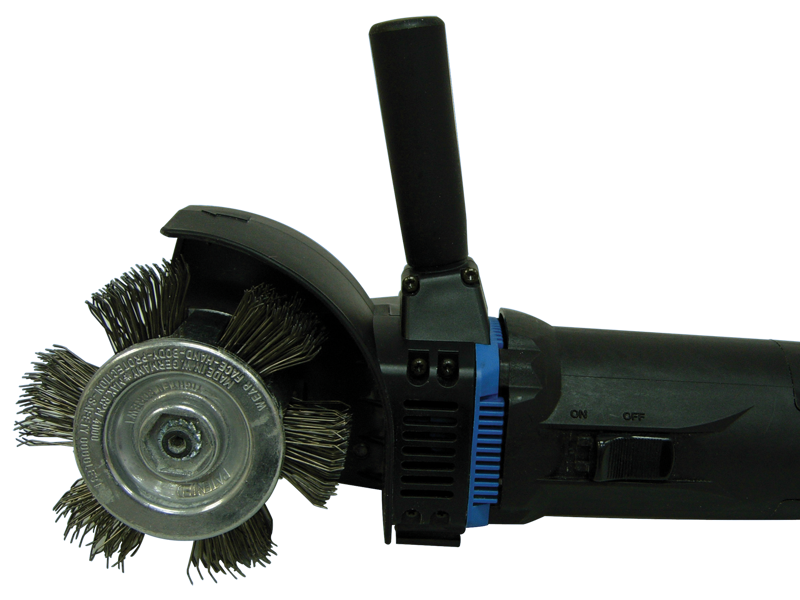

MBX Tool

The MBX Metal Blaster powers specialized wire brush belts that quickly strip epoxy, mesh and ink from aluminum screen frames. The cleaned surface is perfectly textured for bonding new screen mesh.

Squeegee Scrapers

Use the squeegee scraper to spread adhesives, blockouts and screen fillers. Available in 2 & 6" widths (5 & 15 cm).

Adhesive Brushes

Brushes for applying polyurethane adhesives during the screen stretching phase.

Screen Cleaning Brushes

Brushes for spreading reclaim chemicals and screen scrubbing.

Latest news

6/27/2025 1:20:20 PM

SAATI welcomes In&ma students for a real-world industry challenge

SAATI welcomed 20 students from France’s In&Ma École Supérieure de la Performance for a three-days learning experience, turning industrial insight into shared value through cross-border collaboration, talent development and hands-on innovation.

Read more

9/16/2025 8:42:21 AM

Printing United 2025: SAATI presents the LTS E70B

SAATI launches the LTS E70B at Printing United 2025, a breakthrough in textile screen printing technology, uniting precision hardware and AI-driven software to set new benchmarks of efficiency and quality.

Read more

1/20/2026 9:42:26 AM

Top Employer Italy 2026

SAATI has been certified as a Top Employer Italy 2026 for the fourth consecutive year by the Top Employers Institute, the global authority on human resources best practices. This recognition applies to SAATI S.p.A. in Italy and reflects a structured, long-term investment in people policies, working conditions, and organizational culture.

Read more