PA woven fabrics are compatible with a broad spectrum of chemicals, including aliphatic and aromatic hydrocarbons, alkalis, greases, fuels, lubricants, and urea, making them suitable for demanding filtration processes.

)

POLYAMIDE

Home > Filtration > Filter Meshes & Fabrics > PA

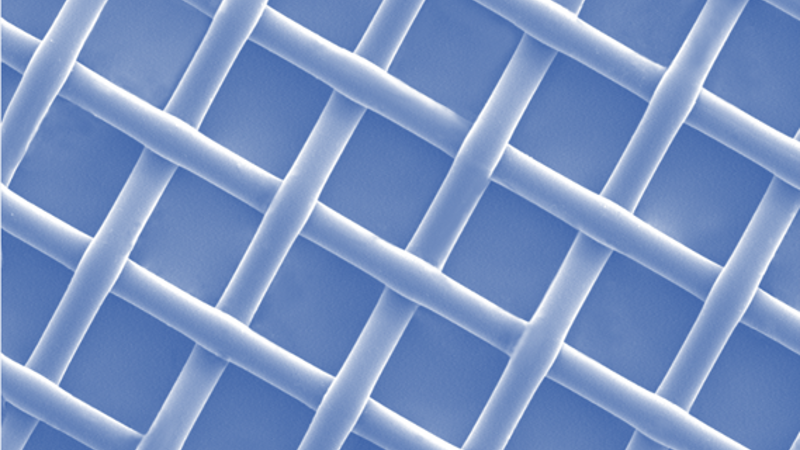

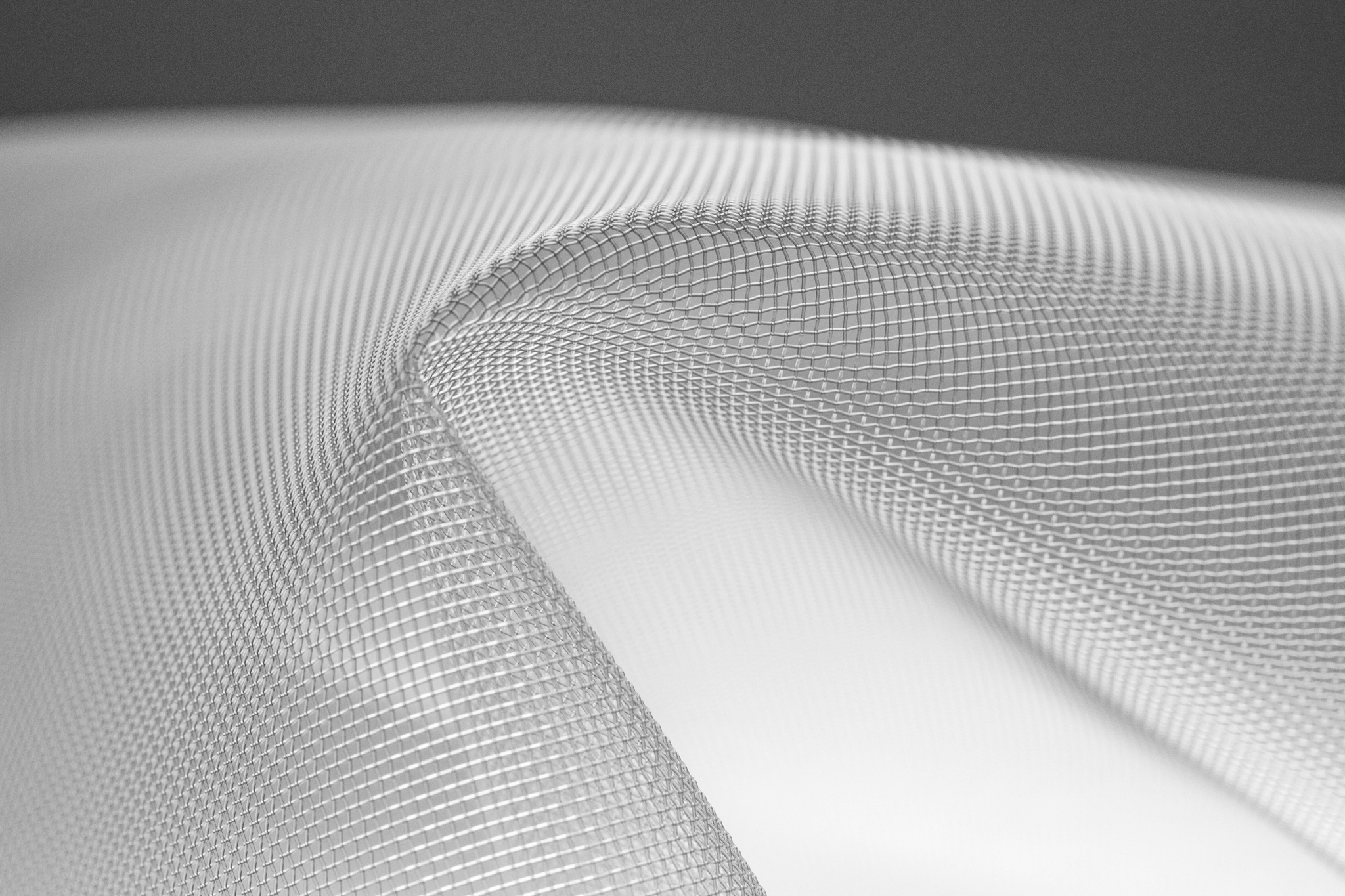

Explore Our Polyamide Woven Meshes

Explore Our Polyamide Woven Meshes

PA woven fabrics are high-performance solutions designed to meet the demanding requirements of a wide variety of industrial filtration applications.

Known for their superior chemical and mechanical resistance, these fabrics offer excellent stability and precision, making them the ideal choice for industries such as automotive, healthcare, and food processing.

Their durability in challenging environments ensures reliable performance across various applications.

Key Benefits

The semi-crystalline structure of PA provides excellent tensile strength and stiffness, ensuring these fabrics maintain their integrity even in high-stress applications.

Compliant with international safety and hygiene standards, PA woven fabrics are ideal for applications in the food and healthcare sectors, ensuring safe and hygienic operation.

These fabrics can operate effectively in environments with high levels of humidity, making them a reliable solution for filtration in moist or wet conditions.

Explore Our Applications

Explore Our Brands

Food & Beverage Processing

The food and beverage industry is a vast and dynamic sector that plays a crucial role in global economies and cultural practices.

It encompasses everything from the production and processing of raw ingredients to the distribution and consumption of final products.

SAATI offers a wide range of solutions for filtration, drying, washing and de-watering processes.

Sifting

Industrial sifting is a crucial operation across various sectors, including food, pharmaceuticals, chemicals, and materials handling.

This process involves the separation and classification of bulk materials based on particle size, ensuring product quality, consistency, and compliance with industry standards.

Milling

SAATImil is SAATI’s dedicated line to the flour milling industry, which includes an extensive selection of fabric types that are manufactured in accordance with ISO 9001:2000 and in compliance with FDA Code of Federal Regulations, as well as with Regulations CE 1935/2004 and EU 10/2011.

Solid / Liquid Separation

Synthetic fabrics for filters produced by SAATI ensure very high precision standards for all liquid filtration operations.

Moreover, equipment especially designed for SAATI, combined with our expert know-how in various fields, allow us to provide fabrics cut to order and customized high quality parts in a wide range of shapes.

Water

Water treatment removes contaminants and undesirable components, or reduces their concentration so that the water becomes fit for its desired end-use.

This treatment is crucial to human health and allows humans to benefit from both drinking and irrigation use.

Automotive

In automotive applications, precise filtration is vital for the performance and longevity of electronic components and fluid systems.

SAATI’s high-performance media enhance efficiency and reliability, ensuring optimal protection for critical vehicle technologies under demanding conditions.

Showing of products

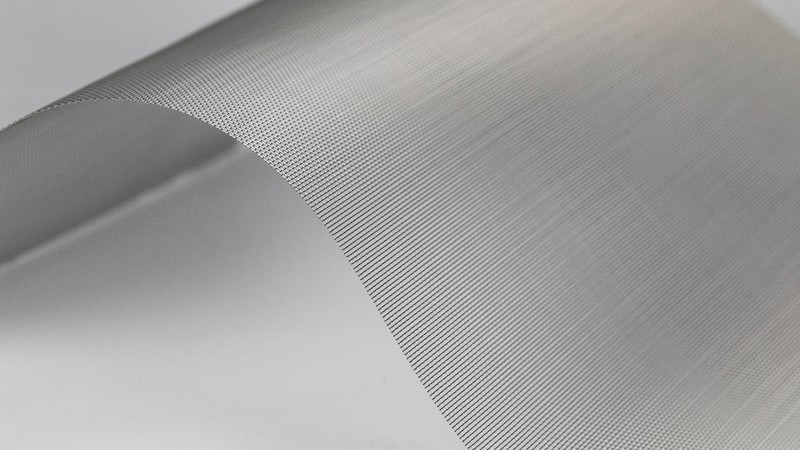

SAATIfil

SAATIfil represents the historical foundation of SAATI’s expertise, offering a comprehensive range of monofilament woven meshes renowned for their precision, consistency, and durability.

Developed with a commitment to quality and innovation, SAATIfil meshes are the essence of simplicity and performance, made from pure polymers without coatings or additives.

COMING SOON - SAATIfil brochure

SAATImil

The SAATImil line is a specialized range of textile products designed specifically for flour milling applications.

This product line focuses on providing high-performance filtration solutions that enhance the quality and efficiency of flour production processes.

With a commitment to innovation and quality, SAATIMIL products meet the unique demands of the milling industry.

Download SAATImil brochure

SAATIcare

SAATIcare fabrics ensure precision and reliability in medical filtration, safeguarding every drop of blood, every breath of air, and every diagnostic result.

Engineered to the highest standards, they provide the unwavering consistency that life-saving applications demand.

Download SAATIcare brochure

SAATImotion

SAATImotion is the explorer of the automotive world, boldly charting the unknown territories of modern vehicle systems.

With the spirit of a seasoned adventurer, it navigates extreme conditions, from intense temperatures to shifting pressures, transforming obstacles into opportunities.

As the journey of every vehicle evolves, SAATImotion provides the essential tools, ensuring that each automotive system performs with unmatched precision and reliability.

Download SAATImotion brochure

EcoFiltra

The EcoFiltra line represents a range of innovative textile products designed specifically for solid-liquid separation applications.

This product line emphasizes sustainability, efficiency, and high-performance filtration solutions suitable for various industries, including wastewater treatment, food processing, pharmaceuticals, and chemical manufacturing.

Download the EcoFiltra brochure

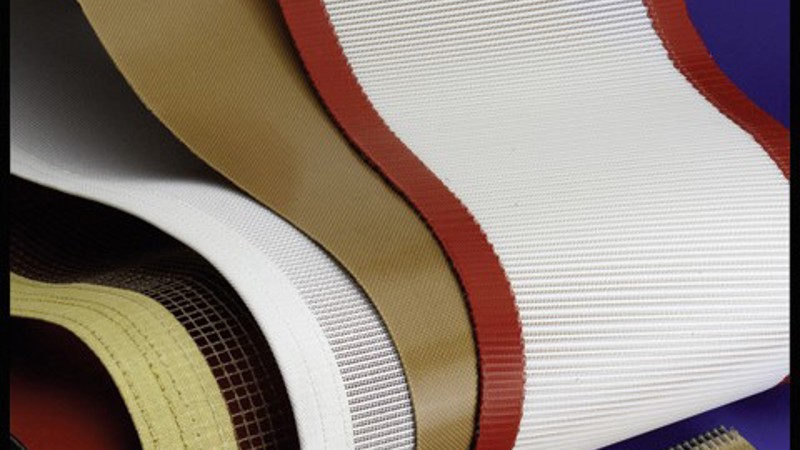

SAATIbelt

The SAATIbelt line is a specialized range of textile products designed specifically for conveyor belt applications.

These products are engineered to provide efficient and reliable performance in various industries, including food processing, chemical, mining, and textile finishing.

The SAATIbelt line emphasizes durability, flexibility, and adaptability to meet the diverse needs of conveyor systems.

Download SAATIbelt brochures

SAATIfil Conductive

The SAATIfil Conductive line is a specialized range of conductive textile products designed specifically for the filtration of powders in ATEX (ATmosphères EXplosibles) conditions.

This product line addresses the critical need for safety and efficiency in environments where explosive atmospheres may be present, such as in the pharmaceutical, chemical, and food processing industries.

Go to SAATIfil Conductive page

Download SAATIfil Conductive brochure

Showing of products

Other Filter Meshes & Fabrics

SAATI offers a wide range of high performance filter meshes and fabrics designed to filter a variety of materials in a wide range of industries.

Produced through a woven process, these fabrics are available in monofilament, multifilament or staple fibers, with polymers such as PET and PA being the most common. For the most demanding environments, specialty options in PEEK and PPS are also available.

PET woven meshes are versatile, high-performance solutions designed to meet the rigorous demands of diverse industrial filtration applications.

These fabrics offer excellent chemical and mechanical resistance, ensuring reliable and precise performance in sectors such as automotive, healthcare, and water treatment.

PPS woven meshes reliably perform in extreme industrial environments. These durable filtration materials offer excellent thermal stability and strong chemical and mechanical resistance.

Trusted by the energy production, automotive processing, and advanced manufacturing sectors, PPS meshes are ideal for critical filtration applications where reliability is paramount.

PP woven meshes provide cost-effective filtration for demanding industrial processes. With excellent chemical resistance and low moisture absorption, these materials maintain consistent performance and accuracy throughout extended use.

Industries including automotive, chemical processing, and water treatment rely on PP meshes for dependable filtration results.

PEEK woven meshes are the premium choice for extreme performance filtration needs.

These advanced materials can withstand the high temperatures and aggressive chemicals that challenge other solutions. They deliver consistent results in environments such as aerospace, high-temperature manufacturing, and precision engineering.

Investing in PEEK technology ensures long-term operational excellence where failure is not an option.

Conveyor belts used in textile and screen-printing applications must meet specific requirements, such as high temperature resistance, dimensional stability and durability.

Two of the most common materials used for their construction are aramid fabrics and glass fiber fabrics, often coated with PTFE (polytetrafluoroethylene). Aramid fabrics, such as Nomex® and Kevlar®, are appreciated for their high thermal and mechanical resistance.

Latest news

6/23/2025 8:50:14 AM

HR Global Summit 2025: One Team, One Vision, One Shared Culture

SAATI’s global HR leaders gathered in Appiano Gentile to align visions, exchange ideas and strengthen a shared culture focused on career development, AI, and employee wellbeing across all our locations worldwide.

Read more

5/28/2025 8:24:26 AM

SAATI sponsors RE-LAKE: the regenerative revolution of Lake Como

SAATI proudly supports RE-LAKE, a groundbreaking project to restore biodiversity in Lake Como through science, sustainability, and local impact. By financing a 1,000 m² underwater meadow, SAATI takes a tangible step toward a regenerative future — right where its story began.

Read more

5/28/2025 8:25:05 AM

SAATI Service Awards: 25 and 30 years of SAATIzens

Each year at its Appiano Gentile headquarters, SAATI hosts the Service Awards Ceremony — a powerful tradition that celebrates employees reaching 25 and 30 years of service. More than a milestone, it’s a tribute to the people who make up the SAATI nation — and a reminder that every contribution, in every department, counts.

Read more

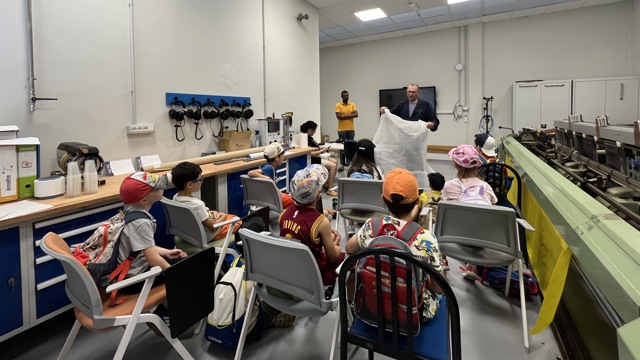

6/23/2025 9:05:45 AM

SAATI welcomes local students into the world of Weaving

SAATI welcomed 17 local school children to our headquarters to explore the world of weaving — connecting tradition, innovation and curiosity in a day of discovery. A meaningful experience that promotes early STEM inspiration.

Read more

6/27/2025 1:20:20 PM

SAATI welcomes In&ma students for a real-world industry challenge

SAATI welcomed 20 students from France’s In&Ma École Supérieure de la Performance for a three-days learning experience, turning industrial insight into shared value through cross-border collaboration, talent development and hands-on innovation.

Read more

9/16/2025 8:42:21 AM

Printing United 2025: SAATI presents the LTS E70B

SAATI launches the LTS E70B at Printing United 2025, a breakthrough in textile screen printing technology, uniting precision hardware and AI-driven software to set new benchmarks of efficiency and quality.

Read more