Continuous processing reduces downtime and increases throughput, making operations more efficient.

Explore Our Cooking - Pasteurization Belts

Explore Our Cooking - Pasteurization Belts

A conveying belt brings the product inside the treatment chamber and two ramps, above and below the conveying belt, distribute the steam with jet system across the entire surface which is going to be treated

In cooking equipment we have lines that take advantage of heated water to cook the immerged product coming from the previous process phase. The lines include cooling and washing machines before preparing the product for packaging. Machine are containing conveyor belts that brings the product inside a cooking vessel with heated water.

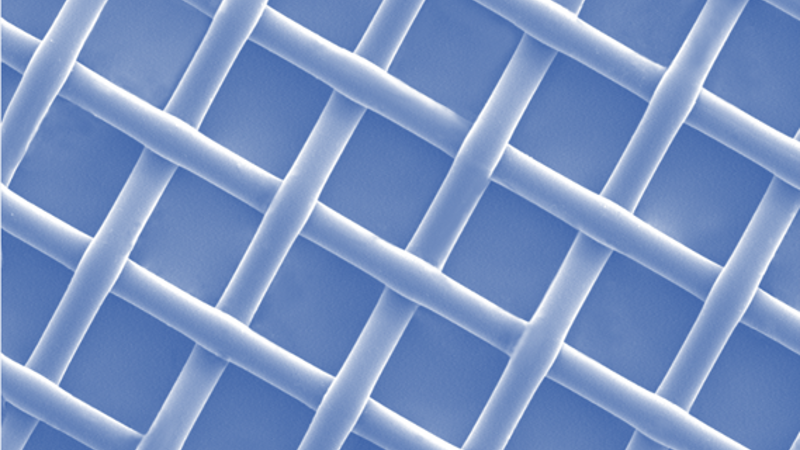

SAATIbelt and SAATIfil products are used in these processes, thanks to the idrolysis resistance and the compliance with food regulations. Mesh belts are crucial in food processing, particularly during cooking and pasteurization. These conveyor systems facilitate efficient heat transfer, product handling, and overall process management.

Purpose of Mesh Belts in Cooking and Pasteurization

- Uniform Heat Distribution: Mesh belts allow for even cooking or pasteurization by maximizing surface area exposure to heat, ensuring consistent temperature throughout the product.

- Efficient Product Flow: They enable continuous movement of products through cooking or pasteurization chambers, improving overall processing efficiency.

- Hygiene and Safety: Designed for easy cleaning, mesh belts help maintain hygiene standards in food processing.

Key Benefits

Explore Our Applications

Explore Our Brands

Other Belting

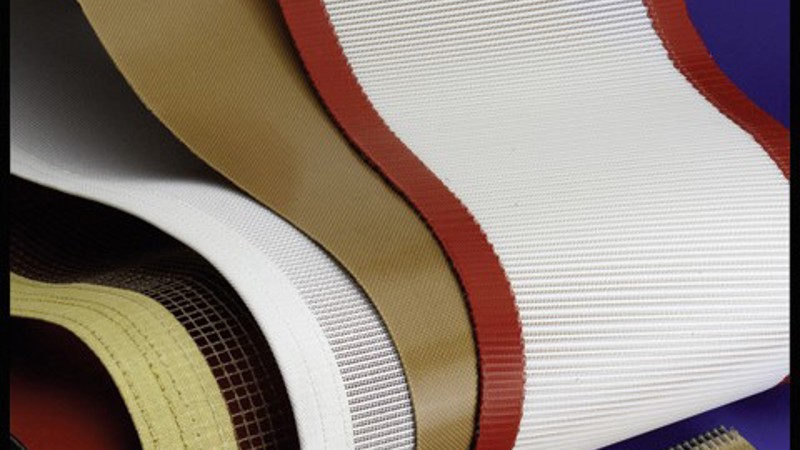

SAATI conveyor belts are made with innovative materials and cutting-edge technologies, ensuring high mechanical resistance, dimensional stability and long operational life.

Available in different configurations, they can be used in applications that require resistance to extreme temperatures, non-stick properties, air permeability or compatibility with sterile and regulated environments.

)