The world-class range of SAATI reclaim chemicals ensures that your screens are always ready for their next task. Execute quick colour changes with our precision-formulated press washes. Simplify your chemical inventory with high-efficiency, universally effective ink removers. Strip stencils with ease using highly concentrated stencil removers that can also degrease the mesh, and where necessary, blast away ghost images with low-odour, fast-acting haze removers. No matter what needs to be done, SAATI has the targeted product to do it.

emulsion removing

SAATI Remove ER Emulsion Removers

Home > Screen Printing > SAATI Chemicals > Reclaim > Emulsion Remover

SAATI Emulsion Removers

SAATI Emulsion Removers

Chemicals for breaking down emulsion on screens during screen recycling. SAATI offers Emulsion Remover products which are universally effective chemistry, with individual added benefits.

Remove ER4

- Ready to use gel emulsion remover

- Easy to apply by brush

- Smooth gel that spreads easily and stays put, for maximum effectiveness

- Contains built in degreaser that cuts through any ink/solvent residue to ensure fast and efficient stencil removal

Remove ER1

- Concentrated emulsion remover powder that dissolves in water to produce stencil stripper solution

- Economical

- Highly concentrated product

- Recommended to be dissolved at 1% by weight in water for full strength working solution for spray application

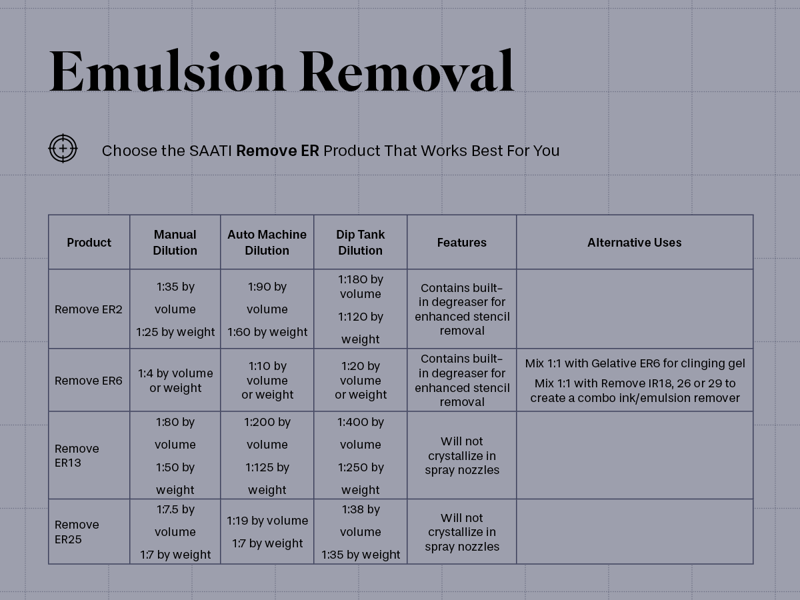

Remove ER2

- Liquid concentrated emulsion remover that includes powerful built-in degreaser

- Dilute 1:35 by volume, or 1:25 by weight to provide full strength working solution for spray application

- Very easy to dissolve and will not crystallize

- Degreaser cuts through any greasy film left after ink removal and this ensures fast and efficient stencil removal

Remove ER5

- Liquid concentrated emulsion remover that mixes 1 part product with 4 parts water

- Economical product for spray application

- Very easy to dissolve and will not crystallize

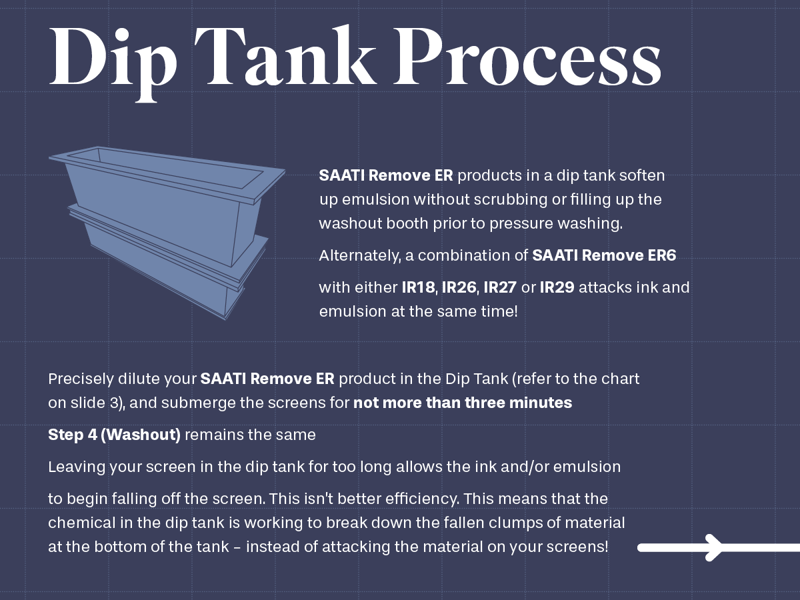

Remove ER6

- Concentrated emulsion remover used for dip tank reclaiming of textile screens

- Mix 1:10 with water for optimum results

- When mixed with SAATI Remove IR18, the solution is used as one-step process for ink and stencil removal

- Long lasting and economical

Remove ER6 Plus

- Emulsion remover concentrate that is mixed with Gelative ER6, to make a reclaiming gel for textile screens

- Mix 1:1 with Gelative ER6 for optimum results as spray on ‘dip tank in a bottle’ process

- Easily applied by spray, or brush, and allows for batch reclaiming of multiple screens

- Stays put where applied for maximum effectiveness

- Fast acting and economical, no waste

Gelative ER6

- Produces clear stable gel when mixed with Remove ER6 and removes ink and emulsion in one easy step

- Works with all photo emulsions and capillary film

- Clings to screen for maximum efficiency

- Boosts cleaning power to minimize ghost image

Super Effective Chemicals, with Renewable & Sustainable Options

Wide-Ranging Adhesives for Screen Printing

Glue fabric onto any type of screen printing frame – from wood to painted metal to aluminium – and achieve excellent fabric coverage with our complete series of Ultrafix SB Plus frame glues, including brushes and products for adhesive removal. Ensure high strength and resistance by preventing fabric from detaching from the frame, and take advantage of fast drying times to accelerate production and related cost reductions.

For flat textile & garment printing, fix your substrate in place with carefully formulated Ultrafix PT Pallet Adhesives.

Maximize Coating Quality with a Chemically Treated Mesh Surface

Prepare both new and recycled mesh for optimal coating quality and stencil adhesion with SAATI mesh preps & degreasers

World Class SAATI Emulsion

Find emulsions suiting all of your screen printing needs for graphics, electronics, textiles or glass. Get the image reproduction you require with fewer steps, enhance your print acuity and choose products formulated for computer-to-screen. Designed to meet a range of customer needs, our SAATIgraf, SAATItex and SAATIvit lines offer the stencil solution you can’t find anywhere else in the industry.

Increase Water Resistance or Create Permanent Waterproof Stencils

Create durable, permanent stencils for both repeat jobs and high-volume prints using SAATI’s Fixer line of screen hardeners. Upon treatment, compatible SAATI emulsions retain the original resolution and definition but gain the enhanced water and/or solvent resistance that will ensure a greater preparedness and productivity.

Best in Class Stencil Films for All Printers

Achieve exceptional definition and resolution quality – with outstanding solvent resistance and even an option for water resistance – with our range of diazo-based, dual-cure and pure photopolymer capillary films. Suitable for use with solvent-based, UV and co-solvent inks, with a range of high-density films for the textile industry, our DCF Supersharp capillary film is a first for the screen printing industry.

Targeted Chemical Formulations, and Convenient Screen Sealers

Complete the screen preparation phase quickly and easily using our range of blockouts and fillers. Designed to meet the needs of all screen printing sectors, our extensive series of blockouts boast either high chemical or water resistance and spread smoothly, thanks to their special rheological properties.

Super Effective Chemicals, with Renewable & Sustainable Options

The world-class range of SAATI reclaim chemicals ensures that your screens are always ready for their next task. Execute quick colour changes with our precision-formulated press washes. Simplify your chemical inventory with high-efficiency, universally effective ink removers. Strip stencils with ease using highly concentrated stencil removers that can also degrease the mesh, and where necessary, blast away ghost images with low-odour, fast-acting haze removers. No matter what needs to be done, SAATI has the targeted product to do it.

For Clean, Nourished Skin

Cut through inks, grease and other oily dirt with precision-formulated SAATI hand cleaners. Our cleaners balance rapid solvency, pleasant aromas, mild abrasives and a triple blend of moisturizing ingredients that protect and condition your skin.

SAATI Emulsion Remover

Chemicals for breaking down emulsion on screens during screen recycling. SAATI offers Emulsion Remover products which are universally effective chemistry, with individual added benefits.

0 products

Ready-Use Emulsion Remover

Ready-Use Emulsion Remover

Remove ER4

- Ready to use gel emulsion remover

- Easy to apply by brush

- Smooth gel that spreads easily and stays put, for maximum effectiveness

- Contains built in degreaser that cuts through any ink/solvent residue to ensure fast and efficient stencil removal

Concentrated Emulsion Remover

Concentrated Emulsion Remover

Remove ER1

- Concentrated emulsion remover powder that dissolves in water to produce stencil stripper solution

- Economical

- Highly concentrated product

- Recommended to be dissolved at 1% by weight in water for full strength working solution for spray application

Concentrated Emulsion Remover

Concentrated Emulsion Remover

Remove ER2

- Liquid concentrated emulsion remover that includes powerful built-in degreaser

- Dilute 1:35 by volume, or 1:25 by weight to provide full strength working solution for spray application

- Very easy to dissolve and will not crystallize

- Degreaser cuts through any greasy film left after ink removal and this ensures fast and efficient stencil removal

Concentrated Emulsion Remover

Concentrated Emulsion Remover

Remove ER5

- Liquid concentrated emulsion remover that mixes 1 part product with 4 parts water

- Economical product for spray application

- Very easy to dissolve and will not crystallize

Concentrated Emulsion Remover

Concentrated Emulsion Remover

Remove ER10

- Economical

- Most concentrated liquid reclaimer

- Dilutes 1:80 by volume or 1:50 by weight to make full strength working solution for spray application

- Can be diluted up to 300:1 by volume or 200:1 by weight, depending on requirements for use in automated screen recycling systems

- Will not crystallize or block spray nozzles

Concentrated Emulsion Remover

Concentrated Emulsion Remover

Remove ER13

- Super concentrated liquid emulsion remover

- Economical

- Highly concentrated liquid reclaimer

- Dilutes 1:40 by volume or 1:25 by weight to make a full strength working solution for spray application

- Can be diluted up to 150:1 by volume or 100:1 by weight, depending on requirements for use in automated screen recycling systems

- Will not block spray nozzles

Concentrated Emulsion Remover

Concentrated Emulsion Remover

Remove ER25

- Low cost liquid concentrated emulsion remover

- Dilute 1:25 with water to provide working solution

- Easy to dissolve and will not crystallize

- Removes all types of emulsion or capillary film stencils

Concentrated Emulsion Remover

Concentrated Emulsion Remover

Remove ER26

- Low cost liquid concentrated emulsion remover with built-in degreaser

- Dilute 1:25 with water to provide working solution

- Easy to dissolve and will not crystallize

- Removes all types of emulsion or capillary film stencils

Combo Product Emulsion Remover

Combo Product Emulsion Remover

Remove ER6

- Concentrated emulsion remover used for dip tank reclaiming of textile screens

- Mix 1:10 with water for optimum results

- When mixed with SAATI Remove IR18, the solution is used as one-step process for ink and stencil removal

- Long lasting and economical

Combo Product Emulsion Remover

Combo Product Emulsion Remover

Remove ER6 Plus

- Emulsion remover concentrate that is mixed with Gelative ER6, to make a reclaiming gel for textile screens

- Mix 1:1 with Gelative ER6 for optimum results as spray on ‘dip tank in a bottle’ process

- Easily applied by spray, or brush, and allows for batch reclaiming of multiple screens

- Stays put where applied for maximum effectiveness

- Fast acting and economical, no waste

Combo Product Emulsion Remover

Combo Product Emulsion Remover

Gelative ER6

- Produces clear stable gel when mixed with Remove ER6 and removes ink and emulsion in one easy step

- Works with all photo emulsions and capillary film

- Clings to screen for maximum efficiency

- Boosts cleaning power to minimize ghost image

Showing of products

SAATI Emulsion Remover Guide

SAATI Emulsion Remover Guide

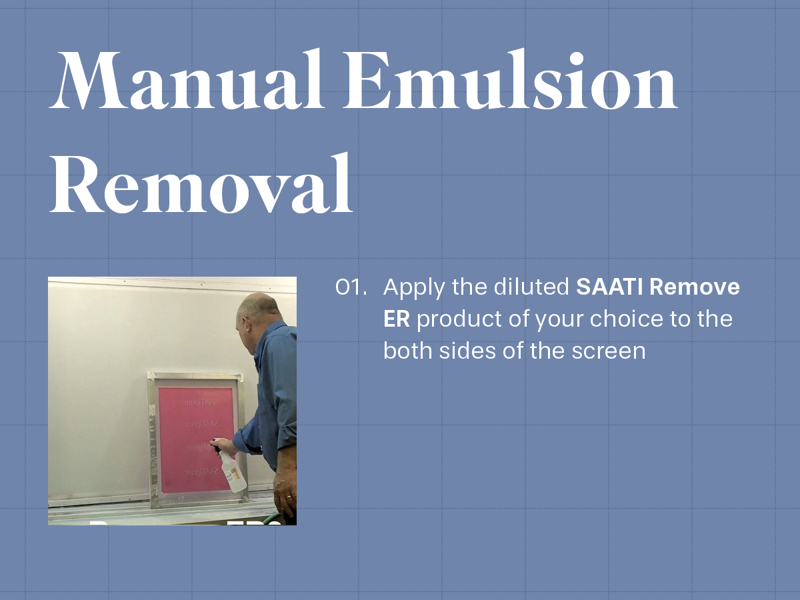

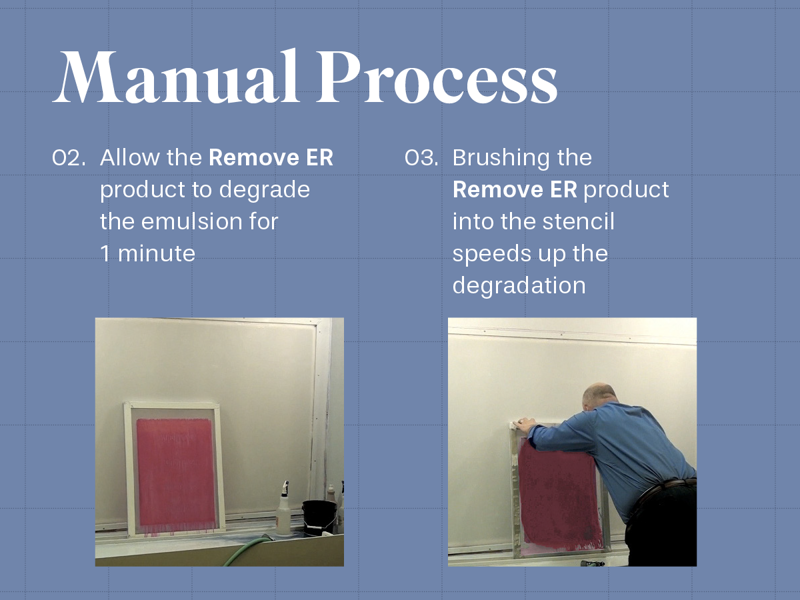

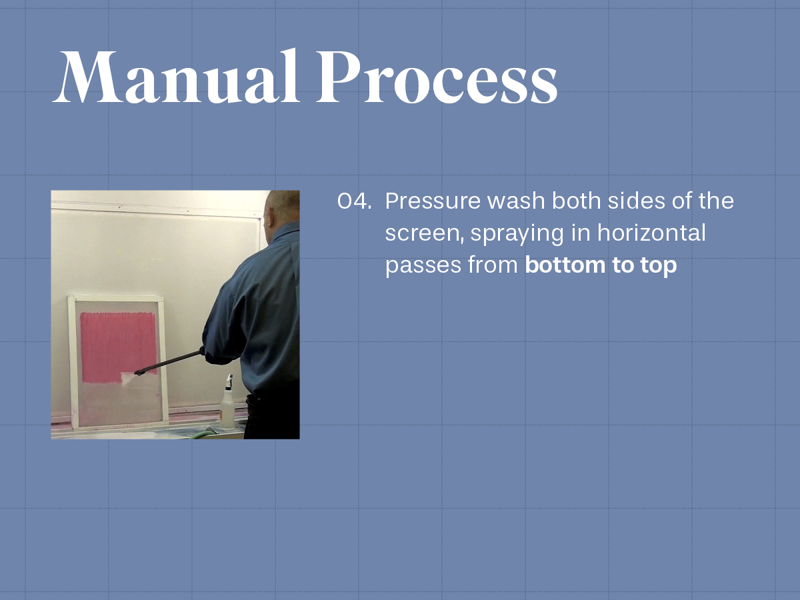

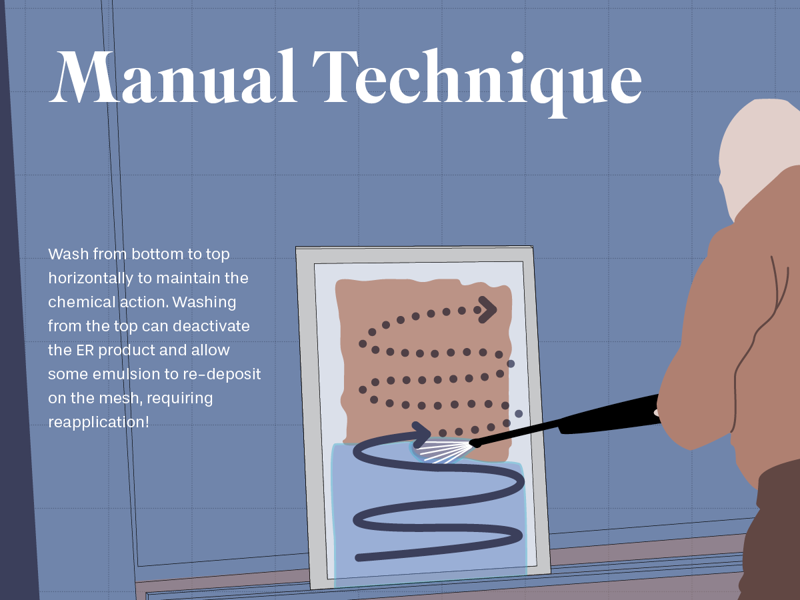

Follow this slide show to optimize your results

when removing emulsion from screens

Follow this slide show to optimize your results

when removing emulsion from screens

Follow this slide show to optimize your results

when removing emulsion from screens

Follow this slide show to optimize your results

when removing emulsion from screens

Follow this slide show to optimize your results

when removing emulsion from screens

Follow this slide show to optimize your results

when removing emulsion from screens

Follow this slide show to optimize your results

when removing emulsion from screens

Follow this slide show to optimize your results

when removing emulsion from screens

Follow this slide show to optimize your results

when removing emulsion from screens

Latest news

6/27/2025 1:20:20 PM

SAATI welcomes In&ma students for a real-world industry challenge

SAATI welcomed 20 students from France’s In&Ma École Supérieure de la Performance for a three-days learning experience, turning industrial insight into shared value through cross-border collaboration, talent development and hands-on innovation.

Read more

9/16/2025 8:42:21 AM

Printing United 2025: SAATI presents the LTS E70B

SAATI launches the LTS E70B at Printing United 2025, a breakthrough in textile screen printing technology, uniting precision hardware and AI-driven software to set new benchmarks of efficiency and quality.

Read more

1/20/2026 9:42:26 AM

Top Employer Italy 2026

SAATI has been certified as a Top Employer Italy 2026 for the fourth consecutive year by the Top Employers Institute, the global authority on human resources best practices. This recognition applies to SAATI S.p.A. in Italy and reflects a structured, long-term investment in people policies, working conditions, and organizational culture.

Read more