Divided by main industries

superior formulations

SAATI Photo Emulsion

Home > Screen Printing > SAATI Chemicals > Emulsion

SAATI Emulsion

PHU-HR Universal Textile Emulsion

Duration | 2 minutes

SAATI Emulsion

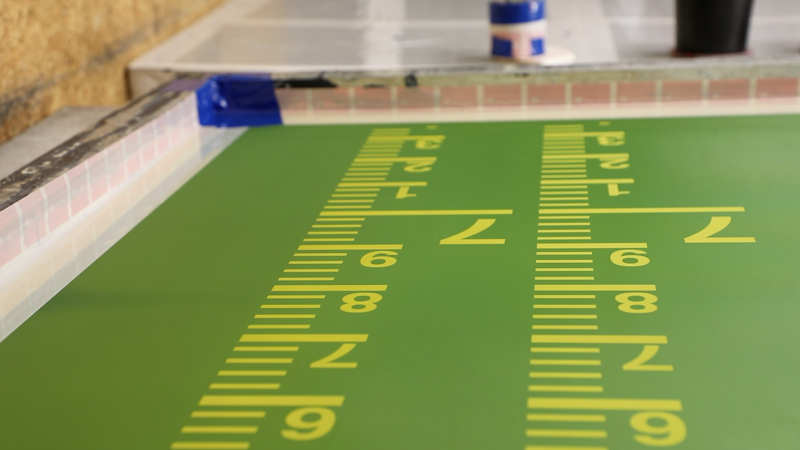

Find emulsions suiting all of your screen printing needs for graphics, electronics, textiles or glass. Get the image reproduction you require with fewer steps, enhance your print acuity and choose products formulated for computer-to-screen. Designed to meet a range of customer needs, our SAATIgraf, SAATItex and SAATIvit lines offer the stencil solution you can’t find anywhere else in the industry.

Products are divided by main industry and further divided by sensitiser technology.

Emulsion & Diazo

0 products

Graphics Emulsion

Graphics Emulsion

Grafic DS

- Diazo emulsion resistant to UV-cured, solvent-based and plastisol ink

- Fast exposing with wide exposure latitude

- Easy to reclaim

- Very economical

Graphics Emulsion

Graphics Emulsion

Grafic DS2

- Diazo emulsion resistant to UV-cured, solvent-based and plastisol ink

- Fast exposing with wide exposure latitude

- Easy to reclaim

- Very economical

Graphics Emulsion

Graphics Emulsion

Grafic HU/HU Violet

- Dual-cure direct emulsion for printing UV-cured, plastisol, solvent-based and water-based inks - general graphics printing

- Excellent print definition on any mesh

- 39% solids content

- Low friction stencil surface prints fine details cleanly and improves durability when used with abrasive inks

Graphics Emulsion

Graphics Emulsion

SAATIgraf HU Fast / HU-DLE

- Faster exposure dual-cure emulsion for CtS stencil making

- Green dual-cure emulsion

- Maximum resolution and edge definition

- Suitable for use with stainless steel wire mesh

- Excellent resistance to water-based, solvent-based and UV-cured inks

- Double the exposure speed of normal dual-cures for use in computer-to-screen systems

Graphics Emulsion

Graphics Emulsion

Grafic HS

- Dual-cure emulsion resistant to UV-cured, solvent-based and plastisol inks for general graphics printing

- Excellent print definition on any mesh

- Superior solvent resistance

- Easy to reclaim

- Economically priced dualcure emulsion available as blue, red violet and clear

Graphics Emulsion

Graphics Emulsion

Grafic HU4

- Dual-cure direct emulsion for printing UV cured, plastisol, solvent-based, and water based inks for general industrial and display graphics & half-tone printing

- Excellent print definition on any mesh

- 37% solids content

- Versatile dual-cure emulsion for use in most graphics applications

Graphics Emulsion

Graphics Emulsion

SAATIgraf HS8

- Faster exposing blue/green dual-cure emulsion for CtS graphics stencil making

- Maximum resolution and good edge definition for industrial printing applications

- Suitable for use with both synthetic and stainless steel wire mesh

- Excellent resistance to solvent-based, UV-Cured, two-part, and plastisol inks

- Fast exposure (for a dual-cure) with wide exposure latitude and easy developing

- Very good solvent resistance and easy reclaiming

- Designed specifically for use with SAATI LTS laser direct exposure system to maximize stencil quality

Graphics Emulsion

Graphics Emulsion

SAATIgraf HS3

- Blue or Violet dual-cure emulsion resistant to UV-cured and solvent-based inks for general industrial, display graphics and half-tone printing

- Excellent print definition on any mesh

- Superior solvent, water & ambient moisture resistance

- Easy to reclaim

- Economically priced dual-cure emulsion

Graphics Emulsion

Graphics Emulsion

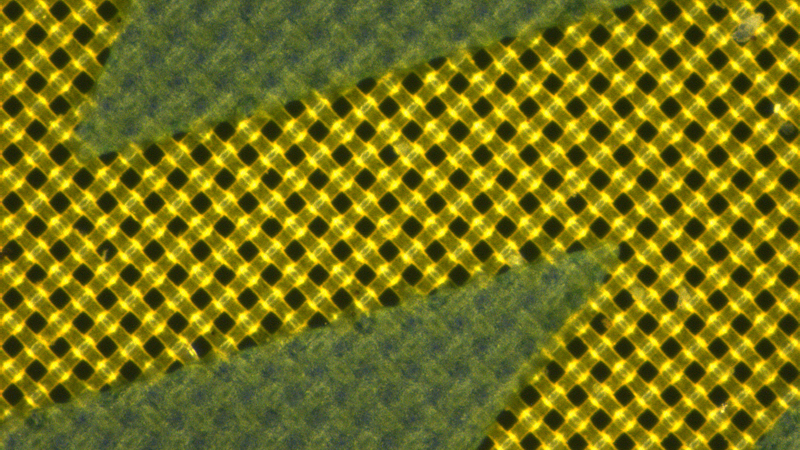

SAATIgraf HSX Blue

- Highly solvent resistant blue dual-cure photoemulsion specially designed for the most demanding industrial printing applications

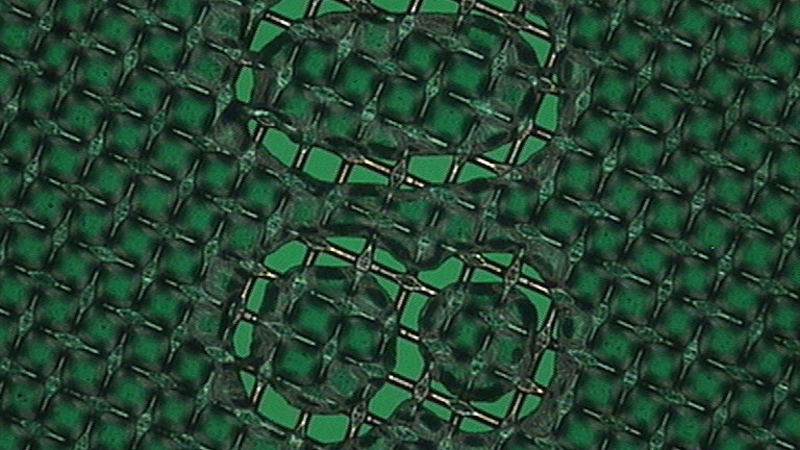

- Extremely high resolution and definition for optimum microreplication

- 37% solids content, medium viscosity

- Optimal performance when EOM is >10 μm

- Excellent resolution/definition combined with smooth sidewall geometry allows clean and faithful microreplication of highly detailed structures and designs

- Sub-micron dual-cure technology provides optimal mesh bridging and product is designed for use with stainless steel and polyester mesh

Graphics Emulsion

Graphics Emulsion

SAATIgraf HSX4

- Highly solvent resistant blue dual-cure photoemulsion specially designed for the most demanding industrial printing applications

- Extremely high resolution and definition for optimum microreplication

- 37% solids content, medium viscosity

- Optimal performance when EOM is >15 μm

- Excellent resolution/definition combined with smooth sidewall geometry allows clean and faithful microreplication of highly detailed structures and designs

- Sub-micron dual-cure technology provides optimal mesh bridging and product is designed for use with stainless steel and polyester mesh

Graphics Emulsion

Graphics Emulsion

SAATIgraf HSX5

- Highly solvent resistant blue dual-cure photoemulsion specially designed for the most demanding industrial printing applications

- Extremely high resolution and definition for optimum microreplication

- 32% solids content, medium viscosity

- Optimal performance when EOM is >15 μm

- Excellent resolution/definition combined with smooth sidewall geometry allows clean and faithful microreplication of highly detailed structures and designs

- Sub-micron dual-cure technology provides optimal mesh bridging and product is designed for use with stainless steel and polyester mesh

Graphics Emulsion

Graphics Emulsion

Grafic PU

- Blue pure photopolymer emulsion for general graphics printing

- Resistant to UV-cured, plastisol and solvent-based ink. Water resistant when post-exposed

- High solids content and medium viscosity for excellent print definition on any mesh

- Easy to reclaim

- Pre-sensitized with no mixing required, long shelf life with consistent performance

- SBQ technology, exposes 4 times faster than two part emulsions and leaves no diazo stains

- Low friction stencil surface for improved durability when used with abrasive inks

Graphics Emulsion

Graphics Emulsion

Grafic PS

- Blue pure photopolymer emulsion for general graphics printing

- Resistant to UV-cured, plastisol and solvent-based ink. Water resistant when post-exposed

- High solids content and medium viscosity for excellent print definition on any mesh

- Exposes 4 times faster than diazo or dualcure emulsions with no mixing required

- Very resistant to solvent and very easy to reclaim

- Make dual-cure quality stencils with 1-part emulsion, and no mixing required, long shelf life & no diazo stains

Graphics Emulsion

Graphics Emulsion

Grafic PS Red

- Red pure photopolymer emulsion for general graphics printing

- Resistant to UV-cured, plastisol and solvent-based ink. Water resistant when post-exposed

- High solids content and medium viscosity for excellent print definition on any mesh

- Exposes 4 times faster than diazo or dualcure emulsions with no mixing required

- Very resistant to solvent and very easy to reclaim

- Make dual-cure quality stencils with 1-part emulsion, and no mixing required, long shelf life & no diazo stains

Graphics Emulsion

Graphics Emulsion

Grafic PS1 Red

- Red pure photopolymer emulsion for general graphics printing

- Resistant to UV-cured, plastisol and solvent-based ink. Water resistant when post-exposed

- Exposes 3 times faster than diazo or dualcure emulsions with no mixing required

- Very resistant to solvent and very easy to reclaim

- Make dual-cure quality stencils with ready-use 1-part emulsion, long shelf life & no diazo stains

Graphics Emulsion

Graphics Emulsion

Grafic PS2 Blue

- Blue pure photopolymer emulsion for general graphics printing

- Resistant to UV-cured, plastisol and solvent-based ink. Water resistant when post-exposed

- Exposes 3 times faster than diazo or dualcure emulsions with no mixing required

- Very resistant to solvent and very easy to reclaim

- Make dual-cure quality stencils with ready-use 1-part emulsion, long shelf life & no diazo stains

Graphics Emulsion

Graphics Emulsion

SAATIgraf CTS

- Universal pure photopolymer emulsion for use with projection exposure equipment

- Excellent resistance to UV-cured, solvent, and water-based ink

- Post-exposure recommended to optimize water resistance for long print runs

- Exposes 20 times faster than diazo or dual cure emulsions

- Easy to reclaim

- High solids content and medium viscosity for high definition stencils on DLE systems

- High exposure speed for high output

Graphics Emulsion

Graphics Emulsion

SAATIgraf CTS4

- Fast exposing SBQ photo emulsion designed for use with computer to screen direct exposure systems

- Universal pure photopolymer emulsion for use with projection exposure equipment

- Excellent resistance to UV-cured, solvent, and water-based ink

- Easy to reclaim with no diazo stains

- Post-exposure recommended to optimize water resistance for long print runs with water-based UV or poster inks

- Exposes 15 times faster than diazo or dual cure emulsions for high productivity

Graphics Emulsion

Graphics Emulsion

SAATIgraf CTS7

- Blue, one part, fast exposing SBQ photo emulsion designed for use with computer to screen direct exposure systems

- Highly solvent-resistant and super easy reclaiming

- Designed for use with all solvent-based and UV-Cured inks

- Exposes 4 times faster than diazo or dual-cure emulsions

- Super easy to reclaim, no pressure washer required

- High resolution and definition for a wide exposure latitude

- 38% solids & medium viscosity for optimum coating quality & stencil performance

Graphics Emulsion

Graphics Emulsion

SAATIgraf CTS9

- Blue, one part, fast exposing SBQ photo emulsion designed for use with computer to screen direct exposure systems

- Highly solvent-resistant and super easy reclaiming

- Designed for use with all solvent-based and UV-Cured inks

- Exposes 4 times faster than diazo or dual-cure emulsions

- Super easy to reclaim, no pressure washer required

- High resolution and definition for a wide exposure latitude

- 38% solids & medium viscosity for optimum coating quality & stencil performance

Graphics Emulsion

Graphics Emulsion

SAATIgraf CTS10

- Blue, one part, fast exposing SBQ photo emulsion designed for use with computer to screen direct exposure systems

- Highly solvent-resistant and super easy reclaiming

- Designed for use with all solvent-based and UV-Cured inks

- Exposes 8 times faster than diazo or dual-cure emulsions

- Super easy to reclaim, no pressure washer required

- High resolution and definition for a wide exposure latitude

- 38% solids & medium viscosity for optimum coating quality & stencil performance

Graphics Emulsion

Graphics Emulsion

SAATIgraf CTS11

- Blue, one part, fast exposing SBQ photo emulsion designed for use with computer to screen direct exposure systems

- Highly solvent-resistant and super easy reclaiming

- Designed for use with all solvent-based, UV-Cured inks & Plastisol inks

- Exposes 10 times faster than diazo or dual-cure emulsions

- Super easy to reclaim, no pressure washer required

- High resolution and definition for a wide exposure latitude

- 40% solids & medium viscosity for optimum coating quality & stencil performance

Textile Emulsion

Textile Emulsion

Textil DW

- Highly water resistant diazo emulsion for use with plastisol and water based inks

- 42% solids content and medium viscosity

- Economical emulsion for apparel printing

- Can be hardened with SAATI Fixer 9 to produce a permanent waterproof stencil

Textile Emulsion

Textile Emulsion

Textil DW3

- Highly water resistant diazo emulsion for use with plastisol and water based inks in flat textile printing, garment printing

- 41% solids content and medium viscosity

- Most economical emulsion for apparel printing

- Can be hardened with SAATI Fixer 9 to produce a permanent waterproof stencil

Textile Emulsion

Textile Emulsion

Textil DV

- Diazo emulsion for use with plastisol and water based inks

- 42% solids content and medium viscosity

- Faster exposure (60%) than is normally required for this type of emulsion

- Economical emulsion for apparel printing

- Can be hardened with SAATI Fixer 9 to produce a permanent waterproof stencil

Textile Emulsion

Textile Emulsion

SAATItex HT / Textil HT

- Blue triple-cure emulsion for printing plastisol and water based inks

- High resolution and definition

- Very easy to reclaim before use of hardener

- Can be catalyzed with SAATI Chemicals Fixer 9 to produce a permanent water proof stencil

- 48% solids and high viscosity for easy coating on wide range of mesh counts

Textile Emulsion

Textile Emulsion

SAATItex HT3

- Low odor blue triple-cure emulsion for printing plastisol and water based inks

- High resolution and definition

- Very easy to reclaim before use of hardener

- Can be catalyzed with SAATI Chemicals Fixer 9 to produce a permanent water proof stencil

- 48% solids and high viscosity for easy coating on wide range of mesh counts

- Up to double the exposure speed of Textil HT

Textile Emulsion

Textile Emulsion

Textil HT Fast

- Blue triple-cure emulsion for printing plastisol and water based inks

- High resolution and definition

- Very easy to reclaim before use of hardener

- Can be catalyzed with SAATI Chemicals Fixer 9 to produce a permanent water proof stencil

- 48% solids and high viscosity for easy coating on wide range of mesh counts

- Up to 40% faster curing time compared to Textil HT

Textile Emulsion

Textile Emulsion

Textil PV

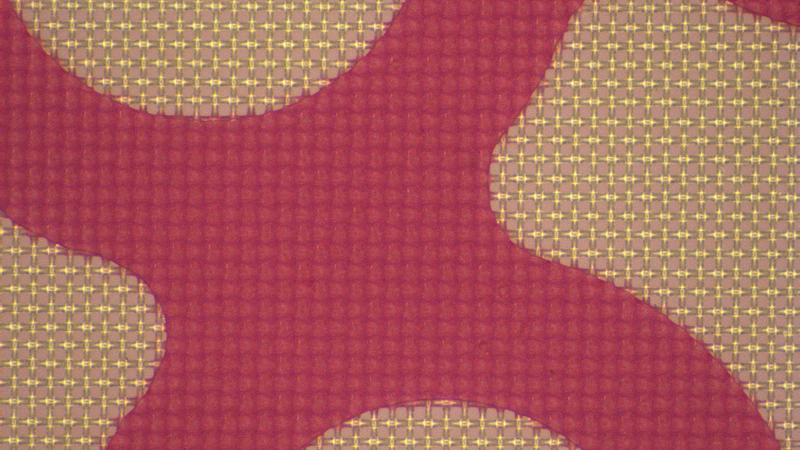

- Red pure photopolymer direct emulsion resistant to plastisol ink, abrasion and humidity

- Exposes 8x faster than a diazo or dual-cure emulsion

- 42% solids content and medium viscosity for easy coating and good bridging on wide range of mesh counts

- No mixing required and no diazo staining

- Water resistant when post exposed

Textile Emulsion

Textile Emulsion

Textil PC Blue

- Blue one part pure photopolymer emulsion resistant to plastisol ink, abrasion and humidity

- Exposes 8X faster than typical two part emulsions

- 50% solids content and medium viscosity for fast build up and good bridging on wide range of mesh counts

- No mixing required and no diazo staining of mesh

- Water resistant when post exposed and can be used to print water based inks and adhesives

Textile Emulsion

Textile Emulsion

Textil PEW

- Very high speed one part photopolymer emulsion designed for projection imaging in flat continuous textile printing plastisol and water based inks

- 36% solids content and low viscosity

- Exposes 30X faster than typical two part emulsions for maximum productivity with DLE computer to screen systems

- Very good resistance to water based inks and can be used for apparel printing as well as flat textile yard goods

- No chemical hardening required and easy to reclaim

Textile Emulsion

Textile Emulsion

Textil PHW Red

- Emulsion for garment printing with plastisol ink, glitter printing, high-density printing

- Red one part pure photopolymer formula resistant to plastisol and high humidity

- High solids content (50%) and high viscosity 50,000 cPs for production of stencils up to 400 micron thick with simple wet-on-wet coating process

- Exposes 10X faster than typical two part emulsions for fast exposure at high build up

Textile Emulsion

Textile Emulsion

Textil PHU

- Red one part pure photopolymer emulsion with universal ink resistance

- Exposes 8X faster than typical two part emulsions

- 45% solids and high viscosity for easy coating and good bridging on all mesh counts

- Universally resistant, can be used with solvent based, UV, and water based inks, yet is easy to reclaim

- Recommended for use with discharge inks as is, without using diazo or catalyst for stencil hardening

- Can be used with Diazo 11 when extra sharpness is required for high resolution

Textile Emulsion

Textile Emulsion

SAATItex PHU Blue

- Blue one part pure photopolymer emulsion with universal ink resistance

- Exposes 8X faster than typical two part emulsions

- 45% solids and high viscosity for easy coating and good bridging on all mesh counts

- Universally resistant, can be used with solvent based, UV, and water based inks, yet is easy to reclaim

- Recommended for use with discharge inks as is, without using diazo or catalyst for stencil hardening

- Can be used with Diazo 11 when extra sharpness is required for high resolution

Textile Emulsion

Textile Emulsion

SAATItex PHU2

- Red one-part pure photopolymer emulsion, no mixing required

- Approximately 4x faster than typical two part emulsion

- 47% solids content and medium viscosity, easy coating on all mesh counts

- Universally resistant: Solvent and waterbased ink resistant, yet easy to reclaim

- Recommended for use with discharge inks as is, without using diazo or catalysts for stencil hardening

- Can be used with Diazo 11 when extra sharpness is required for high resolution

Textile Emulsion

Textile Emulsion

SAATItex PHU-HV

- High Density Garment Printing with HSA water-based or plastisol inks, as well as glitter/crystalina printing through very coarse mesh

- One part pure photopolymer emulsion resistant to water-based and plastisol inks

- High solids content and viscosity enable easy production of stencils for high density printing, as well as being able to cover very coarse mesh

- High solids content (51%) and high viscosity 70,000 cPs for production of 1,000 micron thick stencils with simple wet on wet coating process

- Exposes 10X faster than typical two-part emulsions for fast exposure at high thickness

- Solvent & water resistant and designed for use with HSA water-based inks, as well as plastisol & UV

Textile Emulsion

Textile Emulsion

Textil PHU-HR

- Red one part pure photopolymer emulsion with universal ink resistance

- SBQ technology, exposes 6 times faster than two part emulsions and leaves no diazo stains

- Easy Reclaim

- 42% solids and high viscosity for easy coating and good bridging on all mesh counts

- Universally resistant, can be used with solvent based, UV, and water based inks, yet is easy to reclaim

- Recommended for use with discharge inks as is, without using diazo or catalyst for stencil hardening

Textile Emulsion

Textile Emulsion

SAATItex PHU-MT

- Blue one part pure photopolymer emulsion with universal ink resistance

- Exposes 8X faster than typical two part emulsions

- 45% solids and high viscosity for easy coating and good bridging on all mesh counts

- Universally resistant, can be used with solvent based, UV, and water based inks, yet is easy to reclaim

- Recommended for use with discharge inks as is, without using diazo or catalyst for stencil hardening

- Can be used with Diazo 11 when extra sharpness is required for high resolution

Textile Emulsion

Textile Emulsion

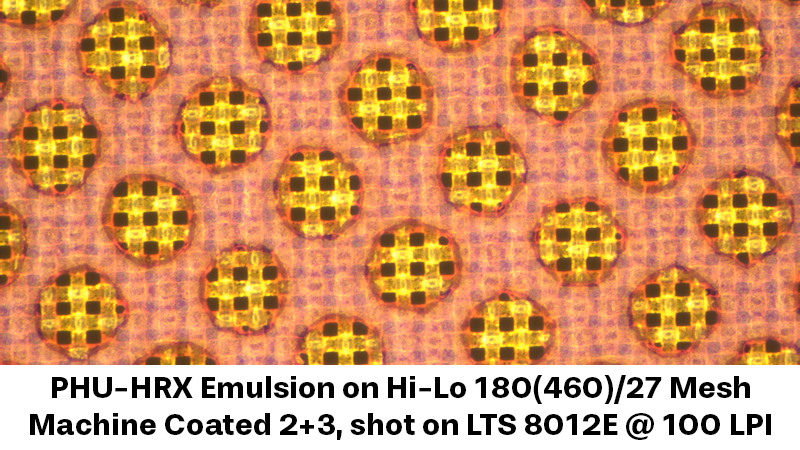

SAATItex PHU-HRX

- Red, one-part photopolymer emulsion with universal ink resistance

- 8x exposure speed for rapid imaging on wide range of mesh counts

- Easy to reclaim

- 48% solids content & high viscosity for easy coating on wide range of mesh counts

- Fast exposing with wide latitude for high resolution stencils

- Resistant to water-base & discharge inks, simply post-expose for maximum durability, and no need for chemical hardener

- Designed to reclaim easily and for use with all automatic reclaim equipment as well as manual use

Textile Emulsion

Textile Emulsion

Textil CTS3

Lorem ipsum odor amet, consectetuer adipiscing elit. Parturient sollicitudin inceptos donec integer dapibus, odio pharetra senectus? Vivamus aliquet platea, augue torquent metus justo varius.

Textile Emulsion

Textile Emulsion

SAATItex PHU-DLE

- Red one-part photopolymer emulsion with universal ink resistance

- 10X exposure speed for rapid imaging on wide range of mesh counts

- Easy to reclaim

- 43% solids content & high viscosity for easy coating on wide range of mesh counts

- Fast exposing with wide latitude for high resolution stencils

- Resistant to water-base & discharge inks, simply post-expose for maximum durability, and no need for chemical hardener

- Designed to reclaim easily and for use with all automatic reclaim equipment as well as manual use

Textile Emulsion

Textile Emulsion

SAATItex Rotary CTS

- Low viscosity one part photopolymer emulsion, compatible with industrial discharges

- Remarkable wet adhesion during the developing process

- Very high mechanical & chemical resistance

- Developed for Direct Light & Direct Laser imaging & exposure

- Excellent resolution for fine lines & half-tone printing

- Outstanding adhesion to nickel screens

Textile Emulsion

Textile Emulsion

SAATItex Rotary DTR

- Blue water-based diazo emulsion

- Excellent adhesion to nickel screens

- Very high mechanical and chemical resistance

- Specifically designed for double squeegee top to bottom coating

- Excellent coating and cosmetic quality on all rotary screen mesh numbers

Glass Emulsion

Glass Emulsion

Vitrum HU

- Dual-cure emulsion for printing UV-cured, solvent-based and water-based inks on electric appliance glass, glass containers and bottles, automotive glass, architectural and decorative glass

- Excellent print definition on any mesh

- 39% solids content

- Low friction stencil surface prints fine details cleanly and improves durability when used with abrasive inks

Glass Emulsion

Glass Emulsion

Vitrum HHU Blue

- Dual-cure emulsion that resists UV-cured, solvent based, water based, and oil based inks, used to decorate flat glass - electrical appliance, automotive, architectural and decorative glass

- Uniform & consistent stencil thickness (a very important characteristic highly appreciated by the automotive glass printing segment)

- Low surface friction properties for improved abrasion resistance and longer stencil life

- 48% solids content and high viscosity for optimum mesh bridging with medium to low mesh counts

Glass Emulsion

Glass Emulsion

SAATIvit PHU2

- Red/blue one-part pure photopolymer emulsion, no mixing required

- Approximately 3x faster than typical two part emulsions

- 42% solids content and medium viscosity, easy coating on all mesh counts

- Universally resistant: UV-cured, solvent-based and water-based UV-cured ink-resistant, yet easy to reclaim

Glass Emulsion

Glass Emulsion

SAATIvit CTS3

- Blue one part pure photopolymer emulsion designed with high speed for use with DLE exposure systems in glass printing applications

- Solvent and water resistant and designed for use with UVcured, solvent or oil based inks used to decorate flat glass

- Post exposure recommended to increase screen durability when used with water based inks

- Exposes 15X faster than typical two part emulsions for maximum productivity

- Designed for use on medium to low mesh counts typically used to decorate automotive glass

Glass Emulsion

Glass Emulsion

SAATIvit CTS4

- Fastest one part pure photopolymer emulsion designed to make screens with DLE exposure systems for flat glass printing

- Solvent and water resistant and designed for use with UV-cured, solvent or oil-based inks used to decorate flat glass

- Exposes 20X faster than typical two part emulsions for maximum productivity

- Designed for use on medium to low mesh counts typically used to decorate architectural glass

Diazo

Diazo

Diazo 11

- Add to SBQ emulsion to maximize sharpness

- Easy to dissolve

- Good stability when stored in original container

- Consistent performance

- Does not affect easy stencil reclaiming

Showing of products

SAATI Chemicals Categories

Wide-Ranging Adhesives for Screen Printing

Glue fabric onto any type of screen printing frame – from wood to painted metal to aluminium – and achieve excellent fabric coverage with our complete series of Ultrafix SB Plus frame glues, including brushes and products for adhesive removal. Ensure high strength and resistance by preventing fabric from detaching from the frame, and take advantage of fast drying times to accelerate production and related cost reductions.

For flat textile & garment printing, fix your substrate in place with carefully formulated Ultrafix PT Pallet Adhesives.

Maximize Coating Quality with a Chemically Treated Mesh Surface

Prepare both new and recycled mesh for optimal coating quality and stencil adhesion with SAATI mesh preps & degreasers

Increase Water Resistance or Create Permanent Waterproof Stencils

Create durable, permanent stencils for both repeat jobs and high-volume prints using SAATI’s Fixer line of screen hardeners. Upon treatment, compatible SAATI emulsions retain the original resolution and definition but gain the enhanced water and/or solvent resistance that will ensure a greater preparedness and productivity.

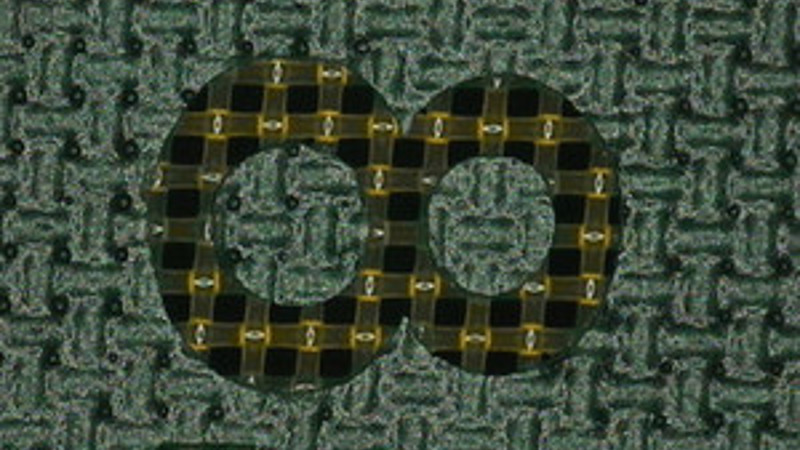

Best in Class Stencil Films for All Printers

Achieve exceptional definition and resolution quality – with outstanding solvent resistance and even an option for water resistance – with our range of diazo-based, dual-cure and pure photopolymer capillary films. Suitable for use with solvent-based, UV and co-solvent inks, with a range of high-density films for the textile industry, our DCF Supersharp capillary film is a first for the screen printing industry.

Targeted Chemical Formulations, and Convenient Screen Sealers

Complete the screen preparation phase quickly and easily using our range of blockouts and fillers. Designed to meet the needs of all screen printing sectors, our extensive series of blockouts boast either high chemical or water resistance and spread smoothly, thanks to their special rheological properties.

Super Effective Chemicals, with Renewable & Sustainable Options

The world-class range of SAATI reclaim chemicals ensures that your screens are always ready for their next task. Execute quick colour changes with our precision-formulated press washes. Simplify your chemical inventory with high-efficiency, universally effective ink removers. Strip stencils with ease using highly concentrated stencil removers that can also degrease the mesh, and where necessary, blast away ghost images with low-odour, fast-acting haze removers. No matter what needs to be done, SAATI has the targeted product to do it.

For Clean, Nourished Skin

Cut through inks, grease and other oily dirt with precision-formulated SAATI hand cleaners. Our cleaners balance rapid solvency, pleasant aromas, mild abrasives and a triple blend of moisturizing ingredients that protect and condition your skin.

Let’s chat screen printing

Do you want to find out more about how we can help with your technical textile manufacturing needs?

Latest news

6/27/2025 1:20:20 PM

SAATI welcomes In&ma students for a real-world industry challenge

SAATI welcomed 20 students from France’s In&Ma École Supérieure de la Performance for a three-days learning experience, turning industrial insight into shared value through cross-border collaboration, talent development and hands-on innovation.

Read more

9/16/2025 8:42:21 AM

Printing United 2025: SAATI presents the LTS E70B

SAATI launches the LTS E70B at Printing United 2025, a breakthrough in textile screen printing technology, uniting precision hardware and AI-driven software to set new benchmarks of efficiency and quality.

Read more

1/20/2026 9:42:26 AM

Top Employer Italy 2026

SAATI has been certified as a Top Employer Italy 2026 for the fourth consecutive year by the Top Employers Institute, the global authority on human resources best practices. This recognition applies to SAATI S.p.A. in Italy and reflects a structured, long-term investment in people policies, working conditions, and organizational culture.

Read more