SAATI belts are resistant to aggressive chemicals used in textile finishing processes (such as dyeing, resin coating and printing).

Explore Our Textile Belts

Explore Our Textile Belts

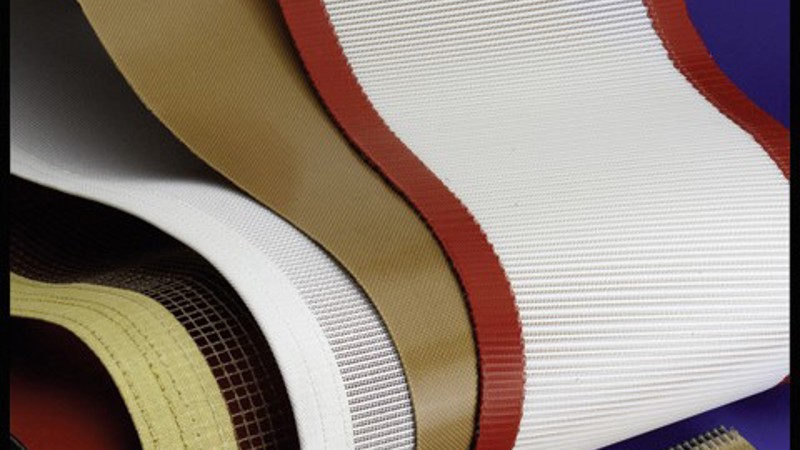

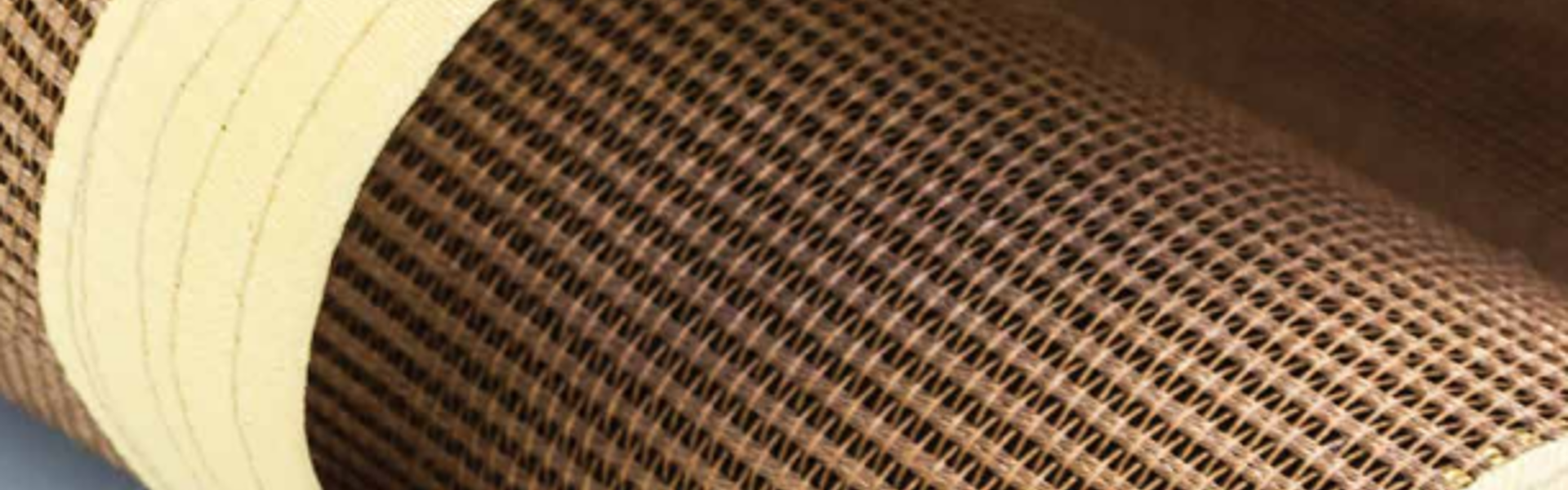

SAATIbelt products begin with selecting a fiber to suit the environment in which the belt will be used. Many different fibers, like hydrolysis-resistant polyester, aramid and glass fiber are available to meet the most critical application requirements.

Hundreds of fibers are taken from spools and aligned precisely on beams prior to the weaving operation. The fibers are then drawn through reeds that keep them spaced evenly. Highly trained and skilled operators weave the fabrics under climate- controlled conditions on computerized looms, many of which have been designed by our own R&D department.

Moreover a full repair service for damaged belts can be provided in certain areas. The woven fabrics are then washed and heat set. This permanently fixes the fabric’s physical properties creating dimensional stability. Afterwards, the fabrics can be surface treated or coated with PTFE or metals.

SAATI Textile Belts are design for:

- Digital/Rotary/Flat Bed Printing Machines

- Screen Printing & UV Dryers Relax Dryers

- Knit: Compactors

- Wool: KD Decatizing Machines & Steamers

- Non-Wovens: Thermobonding Dryers

Key Benefits

Explore Our Applications

Explore Our Brands

Other Belting

SAATI conveyor belts are made with innovative materials and cutting-edge technologies, ensuring high mechanical resistance, dimensional stability and long operational life.

Available in different configurations, they can be used in applications that require resistance to extreme temperatures, non-stick properties, air permeability or compatibility with sterile and regulated environments.

)