For optimal belt tensioning, product distribution, and long product life.

Explore Our Cheese Production & De-watering Belts

Explore Our Cheese Production & De-watering Belts

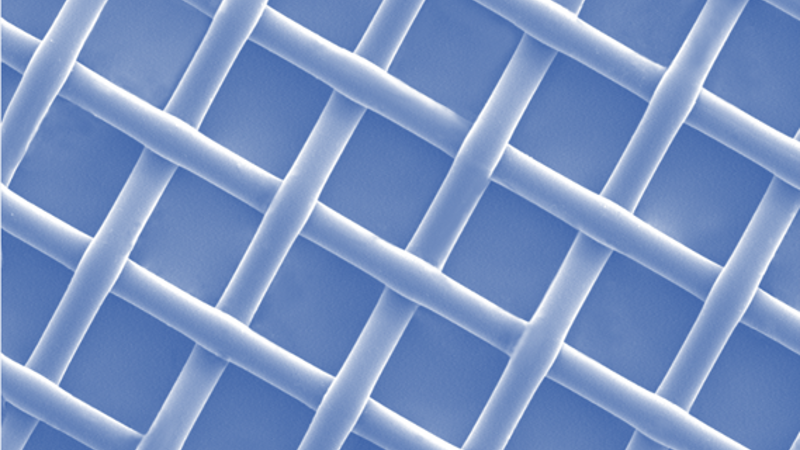

SAATIbelt, designed for dairy production, is the dedicated line for draining, transporting, and processing cheeses. In particular the SAATIbelt is employed to remove whey from the curd while the production of semi-hard and stretched curd (also known as pasta filata) cheese. The high-precision weaving and finishing processes enable SAATI to supply a very consistent and smooth mesh with a uniform pore size and air permeability.

The fabrication process allows for the production of a highly stable belt that can be customized for any type of draining equipment.

Thanks to its stable surface, the SAATIbelt prevents any fines generation during the cheese agitation process. The synthetic material prevents curd from sticking to the belt surface allowing for a quick and effortless cleaning of the belt.

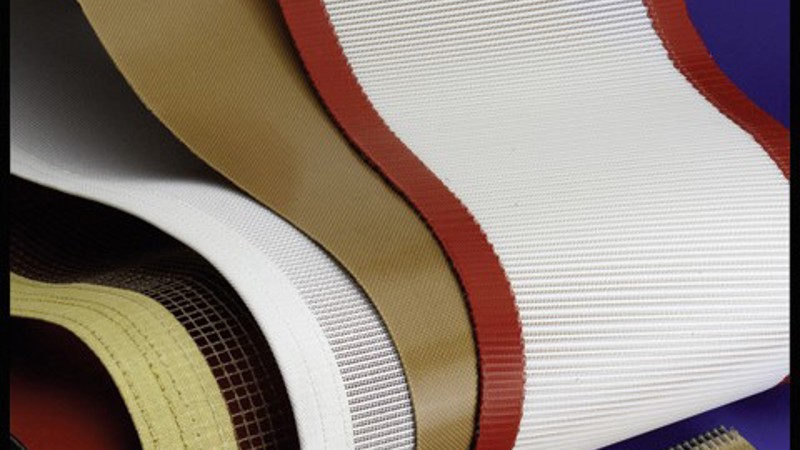

To complete the range, the offer includes also edges and joints that are positioned along the entire belt length to ensure even and stable distribution of the load.

Furthermore:

- Edge coating is available in PET material that is the same as the mesh and that can grant the same resistance and lifetime, with a significant improvement versus the traditional PVC or PU.

- Joint closures are available in different configurations, stainless steel, close ring, PET or PEEK in order to adapt the belt configuration to the different equipment types.

- Guide systems are available in different configurations, the newest trapezoidal and notched PET guides are perfect for small radius cylinders and the low exercise temperatures.

- Polyurethane lathes are available in different width and height, they can also have holes and special surface patterns in order to avoid the “sucker effect” that can complicate product processing and release.

Key Benefits

Explore Our Applications

Explore Our Brands

Other Belting

SAATI conveyor belts are made with innovative materials and cutting-edge technologies, ensuring high mechanical resistance, dimensional stability and long operational life.

Available in different configurations, they can be used in applications that require resistance to extreme temperatures, non-stick properties, air permeability or compatibility with sterile and regulated environments.

)